Modern industrial facilities and laboratory environments demand precise environmental controls to maintain product quality, safety standards, and operational efficiency. The foundation of these controlled environments relies heavily on specialized construction materials that can withstand rigorous cleanliness requirements while providing optimal insulation and structural integrity. Cleanroom panels have emerged as the cornerstone solution for creating these critical spaces, offering unprecedented flexibility in design and functionality to meet diverse industry specifications.

The customization capabilities of these specialized construction systems extend far beyond basic dimensional adjustments. Today's advanced manufacturing processes enable the creation of panels that can accommodate specific pressure differentials, temperature ranges, humidity levels, and contamination control requirements. Industries ranging from pharmaceutical manufacturing to semiconductor production rely on these tailored solutions to maintain the stringent environmental conditions necessary for their operations.

Understanding the various customization options available for cleanroom construction materials empowers facility managers, engineers, and project planners to make informed decisions that optimize both performance and cost-effectiveness. The evolution of panel technology has introduced innovative core materials, surface treatments, and connection systems that address the unique challenges faced by different sectors while maintaining compliance with international standards and regulations.

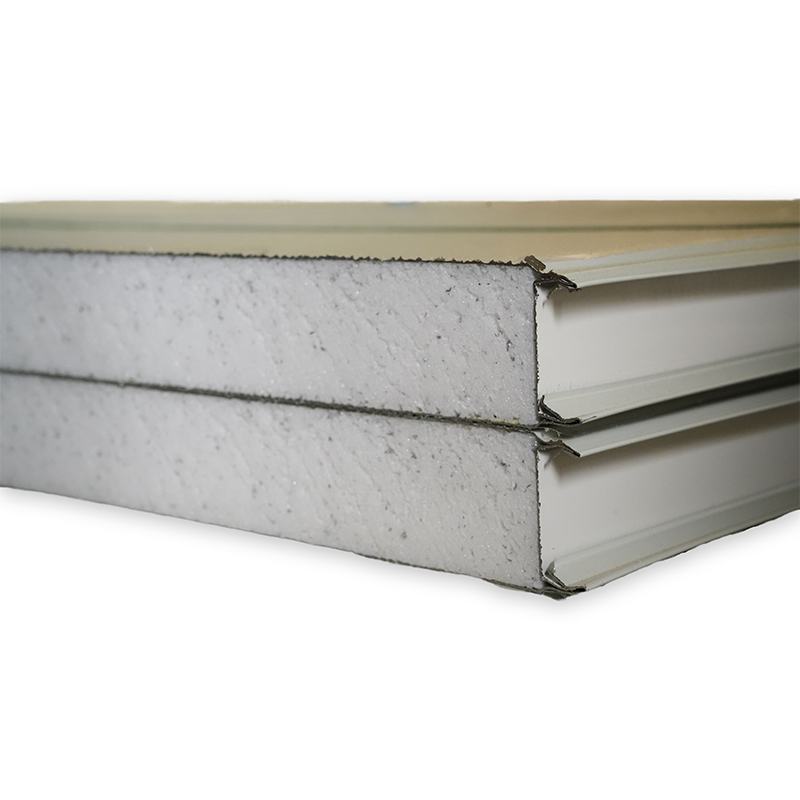

Polyurethane foam cores represent one of the most versatile options for cleanroom panel construction, offering exceptional thermal insulation properties combined with excellent structural stability. The density of polyurethane foam can be customized to meet specific load-bearing requirements while maintaining superior insulation performance. This material exhibits remarkable resistance to moisture absorption, making it ideal for environments where humidity control is critical.

The closed-cell structure of polyurethane foam provides inherent resistance to bacterial growth and contamination, essential characteristics for pharmaceutical and biotechnology applications. Manufacturing processes can adjust the foam density to achieve specific R-values, ensuring optimal energy efficiency for facilities operating under continuous climate control systems. The material's compatibility with various surface treatments allows for seamless integration with different cleanroom classifications and requirements.

Expanded polystyrene cores offer cost-effective solutions for applications requiring moderate insulation performance with lightweight construction benefits. The customization of EPS density enables manufacturers to balance structural requirements with thermal performance, creating panels suitable for diverse installation scenarios. This material demonstrates excellent dimensional stability across varying temperature ranges, maintaining panel integrity in environments with frequent thermal cycling.

The chemical inertness of expanded polystyrene makes it particularly suitable for environments exposed to various cleaning agents and disinfectants commonly used in cleanroom maintenance protocols. Custom thickness options allow designers to optimize wall assemblies for specific thermal bridging concerns while maintaining the required structural performance. The material's low moisture absorption characteristics contribute to long-term durability and consistent performance throughout the facility's operational lifecycle.

Advanced antimicrobial surface treatments have revolutionized cleanroom panels by providing active protection against bacterial and viral contamination. These specialized coatings incorporate silver ion technology or other proven antimicrobial agents that remain effective throughout the panel's service life. The customization of coating formulations allows manufacturers to address specific pathogen concerns relevant to particular industries or applications.

The application process for antimicrobial treatments can be tailored to achieve specific surface textures and appearance characteristics while maintaining the coating's effectiveness. These treatments demonstrate compatibility with standard cleanroom cleaning protocols, ensuring that regular maintenance procedures do not compromise the antimicrobial properties. The durability of these coatings under continuous exposure to disinfectants and cleaning agents makes them essential for high-traffic cleanroom environments.

Chemical-resistant surface treatments address the unique challenges faced by laboratories and production facilities that handle aggressive chemicals or solvents. These specialized finishes can be customized to resist specific chemical families, ensuring long-term performance in corrosive environments. The selection of appropriate surface treatments requires careful consideration of the facility's operational requirements and chemical exposure profiles.

Manufacturing processes enable the creation of surfaces with varying degrees of chemical resistance, from basic solvent resistance to protection against concentrated acids or bases. The customization extends to surface texture options that balance chemical resistance with ease of cleaning and maintenance. These treatments maintain their protective properties while providing the smooth, non-porous surfaces required for effective contamination control in cleanroom environments.

The ability to customize panel dimensions represents a critical advantage in cleanroom construction, allowing designers to minimize seams and joints while optimizing installation efficiency. Standard panel widths can be modified to accommodate specific architectural requirements, reducing waste and improving overall system performance. Custom length options enable the creation of continuous surfaces that minimize potential contamination pathways inherent in multi-panel assemblies.

Thickness customization addresses varying insulation requirements and structural loads, ensuring optimal performance across different applications. The manufacturing flexibility allows for the creation of panels with stepped thickness profiles or integrated features that accommodate building system integration. These dimensional modifications can be achieved without compromising the panel's structural integrity or thermal performance characteristics.

Advanced connection systems represent a significant evolution in cleanroom panel technology, providing seamless integration between adjacent panels while maintaining airtight seals. Custom connection profiles can be designed to address specific installation challenges, such as irregular building geometries or complex architectural features. These systems incorporate gasket technologies that ensure long-term seal integrity under varying environmental conditions.

The development of specialized corner and intersection details enables the creation of continuous cleanroom envelopes without thermal bridges or air leakage pathways. Manufacturing processes can incorporate custom connection features directly into the panel structure, eliminating the need for additional sealing components during installation. These integrated systems reduce installation time while improving overall system performance and reliability.

Pharmaceutical manufacturing facilities require cleanroom panels that meet stringent regulatory requirements while providing optimal contamination control. Custom formulations for surface treatments ensure compatibility with validation protocols and cleaning procedures mandated by regulatory agencies. The panels must demonstrate resistance to repeated sterilization cycles while maintaining their structural and thermal properties throughout their service life.

Temperature and humidity control capabilities can be enhanced through custom core materials and thickness selections that optimize thermal performance for specific process requirements. The integration of transparent sections allows for visual monitoring of production processes while maintaining the integrity of the controlled environment. These customizations must comply with Good Manufacturing Practice guidelines while providing the flexibility needed for efficient facility operations.

Semiconductor manufacturing environments demand cleanroom panels with exceptional stability and minimal outgassing characteristics to prevent contamination of sensitive electronic components. Custom surface treatments eliminate static electricity buildup while maintaining the ultra-clean surfaces required for Class 1 cleanroom environments. The panels must demonstrate dimensional stability under the precise temperature and humidity controls typical of semiconductor fabrication facilities.

Specialized core materials can be formulated to minimize particle generation while providing the structural performance necessary for supporting sophisticated manufacturing equipment. The customization extends to electromagnetic shielding properties that protect sensitive electronic processes from external interference. These applications require panels that maintain their performance characteristics over extended periods while supporting the rapid technological evolution characteristic of the electronics industry.

Comprehensive testing protocols ensure that customized cleanroom panels meet specified performance criteria before installation. Thermal performance testing validates insulation properties under actual operating conditions, confirming that custom core materials achieve their design objectives. Air leakage testing verifies the integrity of connection systems and surface treatments, ensuring compliance with cleanroom classification requirements.

Material compatibility testing evaluates the long-term performance of custom surface treatments under exposure to cleaning agents and operational stresses typical of cleanroom environments. Structural testing confirms that dimensional customizations maintain adequate load-bearing capacity and resistance to wind and seismic loads. These validation procedures provide confidence in the panel's ability to maintain performance throughout its intended service life.

Comprehensive documentation packages accompany customized cleanroom panels, providing detailed specifications and test results that support facility validation and regulatory compliance. Material certifications verify that all components meet relevant industry standards and regulatory requirements. Installation guidelines ensure proper handling and assembly procedures that maintain the panel's performance characteristics.

Quality assurance documentation includes detailed records of manufacturing processes and material traceability information required for regulated industries. Performance data sheets provide the technical information necessary for facility commissioning and validation procedures. These comprehensive documentation packages support the facility's ongoing compliance obligations while providing valuable reference information for maintenance and future modifications.

Proper site preparation forms the foundation for successful cleanroom panel installation, requiring careful attention to substrate conditions and environmental factors. Surface preparation procedures must accommodate the specific connection systems and sealing requirements of customized panels. The installation sequence must consider the unique characteristics of custom panel configurations to ensure optimal performance and appearance.

Environmental conditions during installation significantly impact the long-term performance of cleanroom panels, particularly those with specialized surface treatments or connection systems. Temporary climate control may be necessary to maintain optimal conditions for sealant curing and panel stabilization. The coordination of building systems installation with panel assembly requires careful planning to avoid conflicts and ensure system integration.

Continuous quality control monitoring during panel installation ensures that customized features perform as designed throughout the assembly process. Inspection protocols verify proper panel alignment and connection integrity before proceeding to subsequent installation phases. The verification of sealing system performance through progressive testing prevents costly remediation efforts after construction completion.

Documentation of installation procedures provides valuable feedback for refining customization specifications and improving future projects. Real-time monitoring of environmental conditions during installation helps identify potential issues before they impact panel performance. These quality control measures ensure that the benefits of customization are fully realized in the completed facility.

The selection of core material depends on several critical factors including required thermal performance, structural loads, chemical exposure, and regulatory requirements. Pharmaceutical facilities typically require materials with low outgassing characteristics and resistance to sterilization procedures, while semiconductor applications prioritize dimensional stability and particle generation control. The operating temperature range and humidity levels also influence material selection, as some cores perform better under extreme conditions than others.

Specialized surface treatments generally reduce maintenance requirements by providing enhanced resistance to contamination and chemical exposure. Antimicrobial coatings reduce the frequency of deep cleaning procedures while maintaining effective contamination control. However, certain treatments may require specific cleaning agents or procedures to maintain their effectiveness, which should be considered during the customization planning phase. Proper surface treatment selection can significantly extend panel service life and reduce overall facility operating costs.

Retrofit options depend on the existing panel construction and the desired customization features. Surface treatments can often be applied to existing panels if the substrate is compatible and properly prepared. However, core material modifications or dimensional changes typically require complete panel replacement. Connection system upgrades may be possible in some cases, but require careful evaluation of structural implications and compatibility with adjacent panels.

Lead times for customized cleanroom panels vary significantly based on the complexity of modifications and current manufacturing capacity. Standard customizations such as dimensional changes or common surface treatments typically require 4-6 weeks from order confirmation. Complex customizations involving new material formulations or specialized testing may require 8-12 weeks or longer. Early engagement with manufacturers during the design phase helps identify potential lead time challenges and develop appropriate project schedules.