Modern pharmaceutical and electronics manufacturing facilities operate under strict environmental controls where contamination can result in millions of dollars in lost products and compromised safety standards. The backbone of these controlled environments lies in specialized wall systems that maintain sterile conditions while providing structural integrity and operational efficiency. These advanced building components have revolutionized how sensitive manufacturing processes are protected from external contaminants and environmental variables that could compromise product quality and regulatory compliance.

The pharmaceutical industry faces unprecedented challenges in maintaining sterile production environments while meeting increasingly stringent regulatory requirements from agencies like the FDA and EMA. Electronics manufacturers similarly require ultra-clean environments to prevent microscopic particles from interfering with sensitive semiconductor processes and precision component assembly. Understanding the critical role of specialized wall systems in these applications helps facility managers make informed decisions about infrastructure investments that directly impact product quality, operational efficiency, and regulatory compliance.

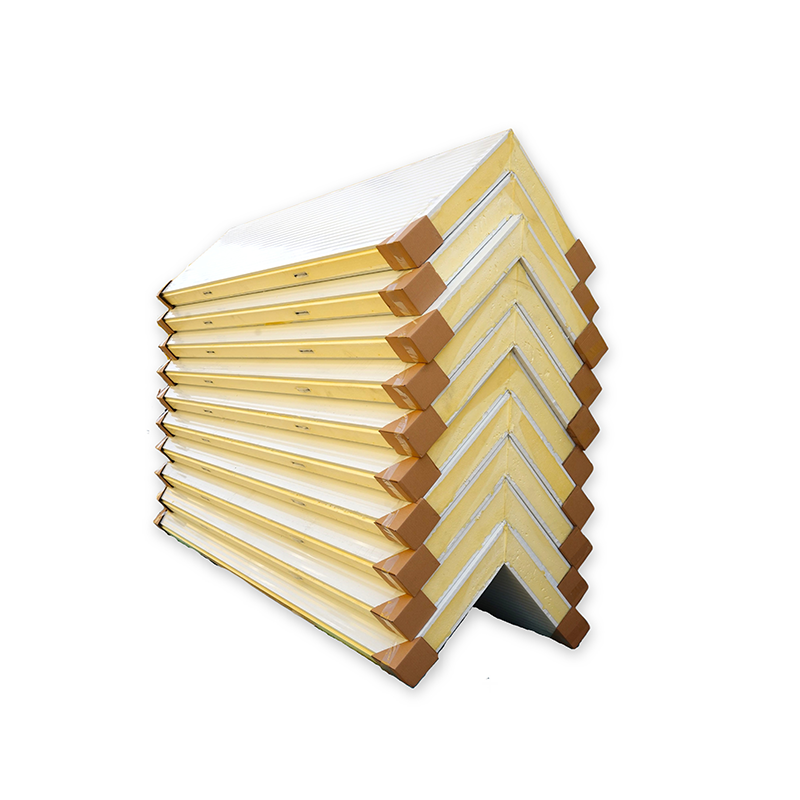

High-performance wall systems designed for controlled environments utilize advanced composite materials that combine structural strength with exceptional barrier properties. The core typically consists of rigid foam insulation materials such as polyurethane or mineral wool, selected for their thermal performance, fire resistance, and dimensional stability. These cores are encased in metal facings, most commonly stainless steel or powder-coated aluminum, which provide the smooth, non-porous surfaces essential for maintaining sterile conditions.

The manufacturing process involves precision bonding techniques that create seamless joints between the core material and metal facings. Advanced adhesive systems ensure permanent lamination while eliminating potential pathways for contamination or moisture infiltration. Quality control measures during production include testing for delamination resistance, thermal performance, and surface integrity to ensure each panel meets the demanding requirements of pharmaceutical and electronics applications.

Surface treatments applied during manufacturing enhance the panels' performance characteristics for specific applications. Anti-microbial coatings inhibit bacterial growth on panel surfaces, while specialized finishes improve chemical resistance and cleanability. These treatments are applied using controlled processes that ensure uniform coverage and long-term durability under repeated cleaning and disinfection cycles.

Modern panel systems incorporate sophisticated joining mechanisms that eliminate gaps and create continuous barrier surfaces throughout the facility envelope. Tongue-and-groove connections, combined with specialized sealants, prevent air leakage and contamination pathways while maintaining structural integrity under varying environmental conditions. These connection systems are engineered to accommodate thermal expansion and building movement without compromising the sealed environment.

Integration features built into panel designs facilitate the installation of essential cleanroom components such as HVAC penetrations, electrical outlets, and observation windows. Pre-engineered mounting systems and standardized cutout dimensions streamline installation while maintaining the integrity of the controlled environment. These features reduce construction time and minimize the risk of contamination during facility commissioning and ongoing maintenance activities.

The modular nature of professional panel systems allows for flexible facility layouts that can adapt to changing production requirements. Standard panel dimensions and connection methods enable efficient reconfiguration of cleanroom spaces without compromising environmental controls. This adaptability proves particularly valuable in pharmaceutical facilities where production lines may need modification to accommodate new drug formulations or regulatory changes.

Effective contamination control begins with the building envelope's ability to prevent uncontrolled air infiltration and particle penetration. Cleanroom panels create continuous air barriers that work in conjunction with HVAC systems to maintain precise pressure differentials and air change rates. The seamless panel surfaces eliminate potential particle accumulation sites while facilitating effective air distribution patterns throughout the controlled environment.

Laboratory testing demonstrates that properly installed panel systems can achieve air leakage rates below 0.1 cfm per square foot at standard test pressures, significantly exceeding the performance of conventional wall systems. This exceptional air tightness enables HVAC systems to operate more efficiently while maintaining the precise environmental conditions required for sensitive manufacturing processes. Reduced air infiltration also minimizes the energy consumption associated with conditioning outside air to cleanroom standards.

The smooth, non-porous surfaces of high-grade panels prevent particle adhesion and facilitate thorough cleaning procedures. Regular particle count monitoring in facilities with properly installed panel systems consistently demonstrates compliance with ISO 14644 cleanliness classifications. Surface roughness measurements typically fall well below the thresholds that could harbor contaminants or interfere with cleaning effectiveness.

Pharmaceutical manufacturing environments expose wall surfaces to aggressive cleaning agents, disinfectants, and chemical vapors that can degrade conventional building materials over time. Specialized panel facings resist attack from common cleanroom chemicals including isopropyl alcohol, hydrogen peroxide, and quaternary ammonium compounds. This chemical resistance ensures long-term surface integrity while preventing the release of particles or contaminants from degraded wall surfaces.

Accelerated aging tests simulate years of exposure to typical cleanroom conditions, demonstrating that quality panel systems maintain their performance characteristics throughout extended service life. Surface hardness, color stability, and adhesion properties remain within acceptable ranges even after thousands of cleaning cycles with aggressive disinfectants. This durability translates to lower lifecycle costs and reduced maintenance requirements compared to alternative wall systems.

Impact resistance testing confirms that professional-grade panels can withstand the mechanical stresses associated with equipment installation, personnel traffic, and routine maintenance activities without compromising surface integrity. Dent and scratch resistance properties help maintain the smooth surfaces essential for effective cleaning while preventing the creation of contamination harboring sites.

The Food and Drug Administration's current Good Manufacturing Practice regulations establish specific requirements for pharmaceutical facility surfaces and environmental controls. Cleanroom panels must demonstrate compliance with 21 CFR Part 211, which mandates that manufacturing areas be designed to prevent contamination and facilitate thorough cleaning and disinfection. Panel systems meeting these requirements undergo extensive testing and documentation to verify their suitability for pharmaceutical applications.

Validation protocols for panel installations include documentation of material composition, surface properties, and installation procedures that affect contamination control performance. These protocols ensure that the installed wall system will consistently maintain the environmental conditions required for drug product safety and efficacy. Regular monitoring and maintenance procedures are established to verify ongoing compliance throughout the facility's operational life.

International harmonization of pharmaceutical regulations means that panel systems must often comply with multiple regulatory frameworks simultaneously. European Medicines Agency guidelines, Japanese PMDA requirements, and other national standards may impose additional constraints on material selection and performance characteristics. Leading panel manufacturers maintain comprehensive documentation packages that address these varied regulatory requirements.

ISO 14644 standards define the classification and testing methods for cleanroom environments, establishing particle count limits and monitoring procedures that directly influence wall system requirements. Panel installations must support the achievement and maintenance of specified cleanliness classifications while facilitating the monitoring activities required for ongoing compliance verification. Surface properties, joint sealing, and integration details all contribute to the facility's ability to meet these exacting standards.

Fire safety standards including NFPA codes and local building regulations impose additional requirements on panel core materials and surface treatments. Flame spread ratings, smoke development indices, and toxicity characteristics must be verified through standardized testing procedures. These safety requirements often necessitate the use of premium core materials and specialized surface treatments that may not be required in less demanding applications.

Quality management systems for panel manufacturing and installation follow ISO 9001 principles to ensure consistent product quality and performance. Documentation systems track material sourcing, manufacturing processes, and installation procedures to provide the traceability required for regulatory audits and facility validation activities.

Successful cleanroom panel installations begin with comprehensive design planning that considers the specific contamination control requirements, operational workflows, and maintenance accessibility needs of the facility. Coordination between architectural, mechanical, and process engineering disciplines ensures that panel layouts support both current production requirements and future expansion possibilities. Early involvement of panel system specialists in the design process helps optimize layouts while avoiding costly modifications during construction.

Structural analysis of the supporting framework ensures adequate load capacity for panel systems while accommodating the connections and penetrations required for utilities and process equipment. Thermal bridging considerations influence the selection of connection details and insulation strategies to maintain temperature control and prevent condensation within the wall system. These engineering evaluations are particularly critical in facilities with extreme temperature differentials or high humidity conditions.

Interface details between panel systems and other building components require careful attention to maintain environmental seals while accommodating building movement and thermal expansion. Floor-to-wall transitions, ceiling connections, and door frame integrations all represent potential contamination pathways that must be properly sealed and detailed. Standardized connection details simplify installation while ensuring consistent performance across the facility.

Installation quality control procedures verify that panel joints, penetrations, and surface conditions meet the specified performance requirements before facility commissioning begins. Visual inspections confirm proper joint sealing and surface finish quality, while pressure testing validates the air barrier performance of the completed installation. These procedures identify and correct deficiencies before they can compromise the controlled environment or require costly remediation.

Commissioning activities include coordination with HVAC system startup to verify that the completed facility achieves the specified environmental conditions. Particle count monitoring, pressure differential measurements, and air change rate verification confirm that the integrated building systems perform as designed. Documentation of these commissioning results provides the baseline data required for ongoing facility validation and maintenance programs.

Training programs for facility maintenance staff ensure proper care and cleaning procedures that preserve panel system performance throughout the operational life of the facility. Understanding of appropriate cleaning agents, techniques, and frequencies prevents damage to panel surfaces while maintaining the sterile conditions required for pharmaceutical and electronics production. These training programs often include hands-on demonstrations and certification procedures to ensure competency in critical maintenance activities.

Cleanroom panels feature specialized surface treatments, enhanced sealing systems, and premium core materials that provide superior contamination control compared to standard industrial panels. The metal facings undergo additional processing to achieve smooth, non-porous surfaces that resist particle accumulation and facilitate thorough cleaning. Joint systems incorporate advanced sealants and gaskets to eliminate air leakage and contamination pathways. Core materials are selected for dimensional stability and resistance to cleaning chemicals, while standard panels may use materials that could degrade under aggressive disinfection procedures.

The exceptional air barrier properties of cleanroom panels significantly reduce uncontrolled air infiltration, allowing HVAC systems to operate more efficiently while maintaining precise environmental conditions. Thermal performance characteristics minimize heat transfer through the building envelope, reducing the energy required for temperature control. The ability to maintain stable pressure differentials with lower air change rates translates to substantial energy savings compared to facilities with less effective wall systems. Over the operational life of a pharmaceutical or electronics facility, these energy savings often exceed the initial premium cost of high-performance panel systems.

Regular cleaning with approved disinfectants maintains surface sterility while periodic inspection of joint sealants ensures continued air barrier performance. Maintenance schedules typically include weekly surface cleaning, monthly detailed inspections, and annual comprehensive assessments of panel condition and environmental performance. Any damage to panel surfaces or joints requires immediate attention to prevent contamination pathways. Replacement of sealants and gaskets follows manufacturer recommendations, typically every five to ten years depending on environmental conditions and usage patterns.

High-quality cleanroom panels designed for pharmaceutical applications typically provide 15 to 20 years of reliable service when properly installed and maintained. The metal facings and core materials resist degradation from chemical exposure and thermal cycling, while advanced joint systems maintain their sealing properties throughout extended service life. Regular maintenance and timely repair of minor damage can extend service life beyond the typical replacement cycle. Facilities planning major renovations or process changes often choose to upgrade to newer panel technologies rather than replace existing systems that continue to meet performance requirements.