Industrial construction projects demand materials that can withstand extreme conditions while maintaining structural integrity over decades of use. Composite panels have emerged as a revolutionary solution, combining multiple materials to create products that offer superior performance compared to traditional single-material alternatives. These engineered solutions integrate various layers of materials, each contributing specific properties to achieve optimal strength, durability, and functionality in demanding industrial environments.

The construction industry has witnessed a significant shift toward advanced materials that can deliver enhanced performance while reducing long-term maintenance costs. Manufacturing facilities, chemical plants, and heavy industrial complexes require building materials that can resist corrosion, thermal expansion, and mechanical stress. These challenging requirements have driven innovation in material science, leading to the development of sophisticated panel systems that combine the best properties of different materials into single, high-performance products.

Understanding the science behind these advanced materials is crucial for engineers, architects, and project managers who need to select appropriate solutions for their specific applications. The layered construction of modern panel systems allows designers to optimize each component for its intended function, resulting in products that exceed the capabilities of traditional materials while often providing cost advantages through reduced installation time and lower maintenance requirements.

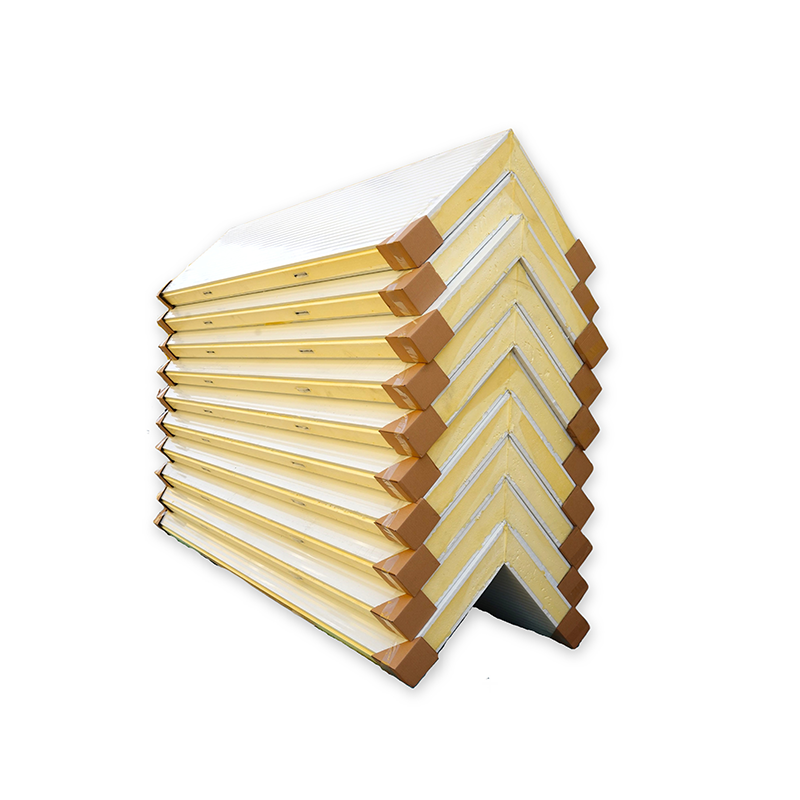

The foundation of high-performance panel systems lies in the sophisticated engineering of core materials that provide structural stability and insulation properties. Polyurethane foam cores have become particularly popular due to their exceptional strength-to-weight ratio and outstanding thermal insulation capabilities. These materials are manufactured through precise chemical processes that create uniform cell structures, ensuring consistent performance across the entire panel surface.

Advanced manufacturing techniques allow for the creation of cores with varying densities and properties throughout different sections of the same panel. This gradient approach enables engineers to optimize performance characteristics for specific load requirements and environmental conditions. The cellular structure of these cores provides excellent energy absorption capabilities, making them ideal for applications where impact resistance is critical.

Material selection for core components involves careful consideration of factors including fire resistance, moisture absorption, and chemical compatibility with facing materials. Modern composite panels incorporate advanced polymer formulations that maintain their properties across wide temperature ranges while resisting degradation from UV exposure and chemical contact.

The outer layers of advanced panel systems serve multiple critical functions, including weather protection, aesthetic appeal, and structural contribution to overall panel performance. Steel facings with specialized coatings provide excellent durability and can be formulated to resist specific chemical environments. These coatings often incorporate nanotechnology to enhance performance characteristics such as scratch resistance and self-cleaning properties.

Aluminum facings offer superior corrosion resistance and lightweight properties, making them ideal for coastal environments and applications where weight reduction is important. The surface treatments applied to aluminum facings can provide enhanced adhesion properties and improved appearance retention over extended service periods.

Fiber-reinforced polymer facings represent the latest advancement in facing technology, offering exceptional strength and chemical resistance while maintaining flexibility for thermal movement accommodation. These materials can be engineered with specific fiber orientations to optimize strength characteristics for particular loading conditions.

Modern panel systems demonstrate remarkable structural performance through their ability to distribute loads across the entire panel assembly rather than concentrating stress in specific areas. The composite action between core and facing materials creates a structural system that performs similarly to an I-beam, with the facings acting as flanges and the core providing shear transfer between them.

Engineering analysis of these systems reveals that properly designed panels can support substantial loads while maintaining deflection limits appropriate for industrial applications. The continuous bond between core and facing materials eliminates the stress concentrations that can occur with mechanical fastening systems, resulting in more predictable and reliable structural performance.

Testing protocols for structural performance evaluation include both static and dynamic loading conditions to simulate real-world service conditions. These comprehensive testing programs ensure that panel systems can maintain their structural integrity throughout their intended service life while accommodating normal building movements and environmental loading conditions.

Thermal performance represents a critical aspect of panel system design, particularly in industrial applications where temperature variations can be extreme. The insulation properties of core materials significantly reduce heat transfer through building envelopes, contributing to energy efficiency and occupant comfort while reducing operational costs.

Thermal expansion management requires careful consideration of material properties and joint design to accommodate movement without compromising panel integrity or weather sealing performance. Advanced panel systems incorporate expansion joints and flexible sealants that maintain their properties across wide temperature ranges.

The thermal bridge effects that can occur with traditional construction methods are virtually eliminated through the continuous insulation provided by panel core materials. This continuous thermal barrier significantly improves building energy performance and helps prevent condensation issues that could lead to durability problems.

Contemporary manufacturing processes for advanced panel systems involve sophisticated automation and quality control systems that ensure consistent product performance. Continuous lamination processes create strong bonds between core and facing materials through precise control of temperature, pressure, and adhesive application rates.

Quality control measures throughout the manufacturing process include real-time monitoring of material properties, dimensional accuracy verification, and performance testing of finished products. Statistical process control techniques help maintain consistent quality while identifying potential issues before they affect product performance.

Advanced manufacturing facilities often incorporate environmental control systems that maintain optimal conditions for material bonding and curing processes. These controlled environments ensure that products meet specified performance criteria regardless of external weather conditions or seasonal variations.

Comprehensive testing programs validate the performance characteristics of panel systems under various loading and environmental conditions. These testing protocols often exceed minimum code requirements to provide additional safety margins and ensure long-term reliability in demanding applications.

Certification processes involve third-party testing laboratories that verify performance claims and ensure compliance with applicable building codes and industry standards. This independent verification provides specifiers and end users with confidence in product performance and reliability.

Ongoing quality assurance programs include regular audits of manufacturing processes and periodic retesting of products to ensure continued compliance with performance standards. These programs help maintain consistent quality and identify opportunities for continuous improvement.

Advanced coating systems provide exceptional protection against corrosion in harsh industrial environments. These multi-layer coating systems often include primer layers that promote adhesion, barrier layers that prevent moisture penetration, and topcoats that provide UV protection and aesthetic durability.

The selection of appropriate coating systems depends on specific environmental conditions including chemical exposure, temperature ranges, and UV intensity. Specialized formulations are available for particularly aggressive environments such as coastal areas, chemical processing facilities, and high-temperature applications.

Regular maintenance programs help ensure continued protection effectiveness throughout the service life of panel systems. These programs typically include periodic inspections and touch-up procedures that address minor damage before it can compromise overall system performance.

Effective moisture management requires careful design of joint systems and drainage details to prevent water infiltration while accommodating normal building movements. Advanced sealant systems maintain their flexibility and adhesion properties across wide temperature ranges and UV exposure conditions.

Pressure equalization systems help prevent wind-driven rain infiltration by managing pressure differences across building envelopes. These systems incorporate carefully designed drainage and ventilation details that allow moisture to escape while preventing its accumulation within wall assemblies.

Vapor barrier systems within panel assemblies help control moisture migration and prevent condensation issues that could compromise insulation performance or lead to durability problems. These systems are designed to work in conjunction with building HVAC systems to maintain appropriate interior humidity levels.

Modern panel systems offer significant advantages in construction scheduling through their ability to be installed quickly and efficiently. Pre-manufactured panels arrive on site ready for installation, eliminating the time required for field fabrication and reducing weather-related construction delays.

Installation techniques have evolved to incorporate specialized fastening systems that provide secure attachment while accommodating thermal movement and building settlement. These systems often utilize concealed fasteners that maintain clean exterior appearances while providing reliable structural connections.

Crew training programs ensure that installation teams understand proper techniques and quality control procedures. These programs help prevent installation errors that could compromise system performance and ensure that warranties remain valid throughout the service life of the installation.

The speed of installation provided by advanced panel systems can result in significant cost savings through reduced labor requirements and shorter construction schedules. These time savings can be particularly valuable in industrial projects where early occupancy provides immediate operational benefits.

Material waste reduction is another significant advantage, as panels are manufactured to precise dimensions and quantities, minimizing on-site waste disposal costs and environmental impact. The controlled manufacturing environment also ensures more efficient use of raw materials compared to field fabrication methods.

Long-term maintenance cost reductions result from the durability and weather resistance of advanced panel systems. These systems typically require less frequent maintenance than traditional materials, resulting in lower lifecycle costs and reduced operational disruptions.

Composite panels offer superior performance through their engineered design that combines multiple materials to achieve optimal properties. The layered construction provides excellent insulation, structural strength, and weather resistance in a single product, eliminating the need for multiple separate components. This integration results in better overall performance, faster installation, and reduced long-term maintenance requirements compared to traditional multi-component wall systems.

Manufacturing quality is maintained through sophisticated automation systems that precisely control temperature, pressure, and material application during production. Continuous monitoring systems track critical parameters throughout the manufacturing process, while statistical process control techniques identify variations before they affect product quality. Third-party testing and certification programs provide independent verification of performance characteristics, ensuring that products meet specified standards consistently.

Advanced panel systems are designed to perform effectively across wide temperature ranges, from extreme cold to high heat conditions. They resist UV degradation, moisture infiltration, and chemical exposure through specialized coating systems and material formulations. The systems accommodate thermal expansion and building movement while maintaining weather sealing integrity, making them suitable for challenging industrial environments including coastal areas, chemical facilities, and high-temperature applications.

Proper installation is critical for achieving the full performance potential of advanced panel systems. Specialized fastening systems and sealing techniques ensure secure attachment while accommodating building movements and thermal expansion. Installation crews must follow manufacturer specifications precisely to maintain warranty coverage and ensure optimal performance. Quality control during installation includes verification of joint sealing, fastener spacing, and alignment to prevent issues that could compromise system durability or weather resistance.