Maintaining sterile environments in laboratories and manufacturing facilities requires sophisticated solutions that can meet stringent contamination control standards. Cleanroom panels have emerged as a critical component in creating controlled environments where even microscopic particles must be carefully managed to ensure product quality and safety. These specialized wall systems provide the foundation for environments where pharmaceutical production, semiconductor manufacturing, biotechnology research, and medical device assembly take place under the most demanding cleanliness requirements.

The importance of proper wall systems in cleanroom construction cannot be overstated, as these surfaces directly impact air quality, contamination levels, and overall facility performance. Modern cleanroom panels incorporate advanced materials and engineering principles to create seamless barriers that prevent particle generation while supporting the complex mechanical systems required for environmental control. Understanding how these panels function and their specific benefits helps facility managers make informed decisions about cleanroom construction and upgrades.

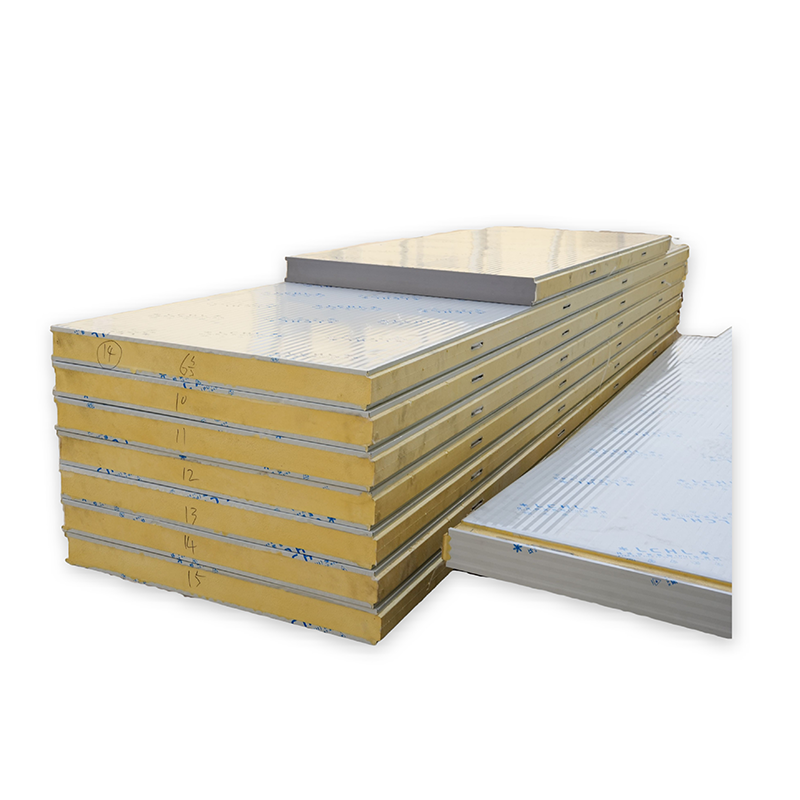

Cleanroom panels utilize specialized core materials that provide both structural integrity and contamination resistance. The most common core materials include polyurethane foam, mineral wool, and honeycomb structures, each offering distinct advantages for specific applications. Polyurethane cores provide excellent insulation properties while maintaining lightweight characteristics, making them ideal for facilities requiring temperature control alongside particle management.

The outer surfaces of these panels typically feature materials such as stainless steel, powder-coated steel, or specialized laminates that resist chemical exposure and particle generation. These surface materials undergo careful selection based on the intended cleanroom classification and the specific contaminants that must be controlled. The seamless integration between core and surface materials ensures long-term performance without degradation that could compromise environmental standards.

The surface characteristics of cleanroom panels play a crucial role in preventing particle accumulation and facilitating effective cleaning protocols. Smooth, non-porous surfaces prevent microbial growth and particle adhesion, while chemical-resistant coatings ensure that aggressive cleaning agents can be used without damaging the panel structure. These properties become particularly important in pharmaceutical and biotechnology applications where sterility requirements are most stringent.

Advanced cleanroom panels incorporate antimicrobial treatments that actively inhibit bacterial and fungal growth on panel surfaces. These treatments remain effective over extended periods, reducing maintenance requirements while enhancing the overall sterility of the controlled environment. The combination of passive surface properties and active antimicrobial protection creates multiple layers of contamination defense.

Proper installation of cleanroom panels requires specialized techniques that eliminate gaps, cracks, and other potential contamination sources. Modern panel systems utilize interlocking mechanisms and specialized sealants that create continuous surfaces without visible joints or seams. These installation methods prevent particle infiltration while maintaining the structural integrity required for supporting ceiling systems and equipment mounting.

The installation process typically involves careful coordination between panel placement and mechanical system integration. Panels must accommodate HVAC penetrations, electrical installations, and other building services while maintaining their contamination control properties. Skilled installers use specialized tools and techniques to ensure that each panel connection maintains the required seal integrity throughout the facility's operational life.

Cleanroom panels must integrate seamlessly with sophisticated air handling systems that maintain precise environmental conditions. The panels provide mounting surfaces for air distribution components while ensuring that these connections do not compromise the controlled environment. Specialized penetration seals and mounting hardware maintain air barrier integrity at every system interface point.

Temperature and humidity control systems rely on the thermal properties of cleanroom panels to maintain stable conditions throughout the facility. The insulation characteristics of panel cores prevent thermal bridging that could create condensation points or temperature variations. This thermal stability supports the precise environmental control required for sensitive manufacturing processes and research applications.

Different industries require varying levels of environmental control, with cleanroom panels designed to support specific classification standards. ISO 14644 standards define particle concentration limits for different cleanroom classes, with Class 1 representing the most stringent requirements. Pharmaceutical manufacturing typically requires Class 7 or Class 8 conditions, while semiconductor production may demand Class 1 or Class 10 environments.

The selection of appropriate cleanroom panels depends on understanding these classification requirements and their implications for panel performance. Higher classification levels demand panels with superior sealing properties, smoother surfaces, and enhanced resistance to particle generation. Panel manufacturers provide detailed specifications that help facility designers select systems capable of supporting their required cleanliness levels.

Cleanroom panels undergo rigorous testing to verify their performance characteristics before installation and during facility validation. Particle emission testing measures the rate at which panels generate contaminants under normal operating conditions. Surface cleanliness testing evaluates how effectively panels can be cleaned and maintained over time.

Ongoing validation procedures ensure that cleanroom panels continue to perform according to specifications throughout their service life. Regular particle monitoring, surface sampling, and visual inspections identify any degradation in panel performance before it affects facility operations. These validation programs provide the documentation required for regulatory compliance in pharmaceutical and medical device manufacturing.

Pharmaceutical facilities benefit from cleanroom panels that support strict contamination control while accommodating frequent cleaning and sanitization procedures. The chemical resistance of panel surfaces allows for the use of aggressive disinfectants without degrading panel performance. Smooth, seamless surfaces prevent the accumulation of cleaning residues that could contaminate subsequent batches.

The modular nature of cleanroom panels enables pharmaceutical facilities to reconfigure production areas as product lines change or expand. Panels can be relocated or replaced without compromising the controlled environment in adjacent areas. This flexibility reduces downtime and construction costs associated with facility modifications.

Research laboratories require cleanroom panels that can support diverse experimental conditions while maintaining consistent environmental control. The thermal stability provided by insulated panels prevents temperature fluctuations that could affect sensitive experiments or equipment calibration. Chemical-resistant surfaces withstand exposure to various research chemicals without degrading or releasing contaminants.

Laboratory cleanroom panels often incorporate features that support equipment installation and utility distribution. Panels can be designed with integrated cable management systems, equipment mounting points, and service penetrations that maintain environmental integrity while providing necessary functionality. These features reduce installation complexity and ensure that research equipment operates under optimal conditions.

Effective maintenance of cleanroom panels requires specialized cleaning protocols that preserve panel integrity while achieving required cleanliness levels. Daily cleaning procedures typically involve wiping surfaces with approved disinfectants using lint-free materials that do not generate particles. The smooth surfaces of quality cleanroom panels facilitate these cleaning procedures while resisting damage from repeated sanitization.

Long-term maintenance strategies focus on preventing panel degradation that could compromise contamination control. Regular inspections identify early signs of wear, damage, or seal failure that require attention. Preventive maintenance programs extend panel service life while ensuring consistent performance throughout the facility's operational period.

The total cost of ownership for cleanroom panels extends beyond initial purchase and installation expenses to include maintenance, energy, and replacement costs over the facility's operational life. High-quality panels may require higher initial investment but typically provide lower lifecycle costs through reduced maintenance requirements and longer service life.

Energy efficiency considerations become increasingly important as facilities seek to reduce operational costs while maintaining environmental performance. Well-insulated cleanroom panels reduce heating and cooling loads, resulting in lower energy consumption and reduced carbon footprint. These efficiency gains accumulate over the facility's operational life, providing significant cost savings and environmental benefits.

Emerging technologies are transforming cleanroom panels from passive barriers into active components of facility monitoring and control systems. Smart panels incorporate sensors that continuously monitor surface conditions, temperature, and even particle levels near panel surfaces. This real-time data enables predictive maintenance and early detection of potential contamination issues.

Integration with facility management systems allows smart cleanroom panels to communicate performance data and alert operators to conditions requiring attention. These capabilities enhance facility reliability while reducing the manual inspection requirements traditionally associated with cleanroom maintenance. As sensor technology advances, panels may incorporate even more sophisticated monitoring capabilities.

Environmental sustainability is driving innovation in cleanroom panel materials and manufacturing processes. Manufacturers are developing panels using recycled materials and bio-based components that maintain required performance characteristics while reducing environmental impact. These sustainable options appeal to organizations seeking to minimize their carbon footprint without compromising operational requirements.

End-of-life considerations are becoming increasingly important as facilities plan for panel replacement or facility decommissioning. Recyclable panel components and design for disassembly principles reduce waste and support circular economy objectives. These sustainable approaches align with corporate environmental goals while maintaining the performance standards required for cleanroom applications.

Pharmaceutical facilities typically require daily cleaning of cleanroom panels using approved disinfectants, with more thorough weekly deep cleaning procedures. Monthly inspections should check for seal integrity, surface damage, and any signs of wear that could affect contamination control. Annual comprehensive evaluations assess overall panel condition and determine if any replacement or repair work is needed to maintain compliance with regulatory standards.

Cleanroom panels with high-quality insulation cores significantly reduce thermal transfer through wall systems, decreasing the load on HVAC equipment required to maintain precise temperature and humidity conditions. The improved thermal envelope reduces energy consumption by up to 30% compared to conventional construction methods. Additionally, the airtight seals between panels prevent infiltration and exfiltration that would otherwise increase conditioning loads.

Many existing facilities can be upgraded with modern cleanroom panels through retrofit installation techniques that minimize disruption to ongoing operations. The modular nature of panel systems allows for phased installation that maintains operational continuity in unaffected areas. However, successful retrofits require careful evaluation of existing structural support, mechanical systems, and clearances to ensure proper integration with new panel systems.

Panel selection depends on required cleanliness classification, chemical exposure conditions, temperature and humidity requirements, fire safety codes, and budget considerations. Higher cleanliness classes require panels with superior sealing properties and smoother surface finishes. Chemical exposure from cleaning agents or process materials may necessitate specialized surface coatings or core materials. Structural requirements and local building codes also influence panel specification and selection criteria.