In modern construction and manufacturing, selecting the right panel system significantly impacts structural performance, cost efficiency, and long-term durability. Engineers and architects frequently debate between honeycomb panels and traditional solid panels when designing buildings, aircraft components, automotive parts, and industrial structures. This comprehensive analysis examines the fundamental differences, advantages, and limitations of both panel types to help professionals make informed decisions for their specific applications. Understanding these distinctions becomes crucial as industries increasingly prioritize lightweight materials without compromising structural integrity or safety standards.

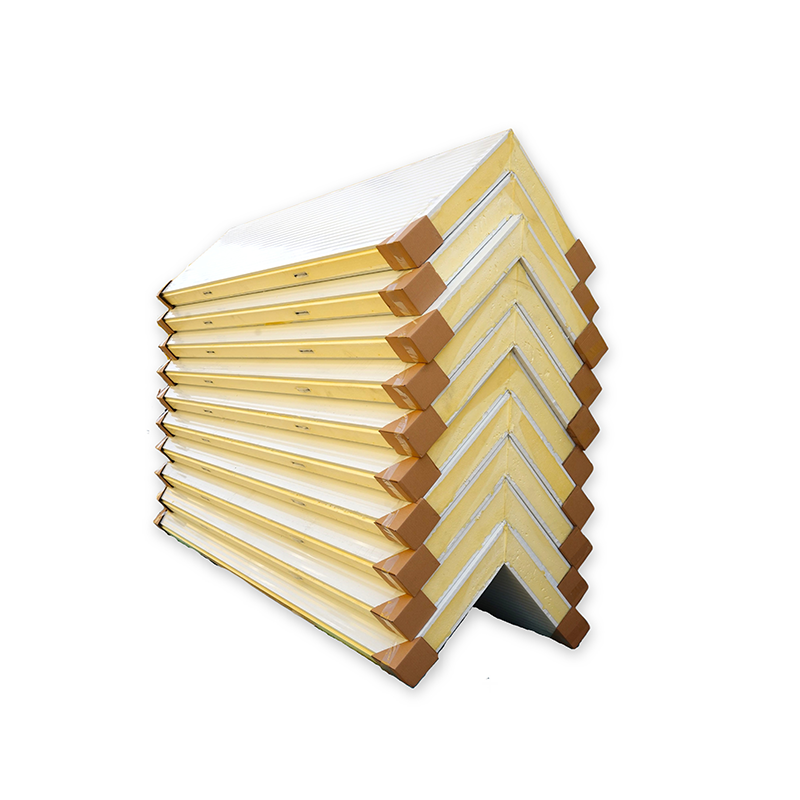

The fundamental difference between honeycomb panels and solid panels lies in their internal structure and material distribution. Honeycomb panels feature a lightweight core made from hexagonal cells sandwiched between two face sheets, typically constructed from aluminum, aramid, or thermoplastic materials. This geometric configuration maximizes strength-to-weight ratios while minimizing material usage. The hexagonal cell pattern naturally distributes loads across multiple points, creating exceptional resistance to compression and bending forces. Manufacturing processes involve bonding face sheets to the honeycomb core using structural adhesives or mechanical fasteners, ensuring uniform load transfer throughout the panel assembly.

Solid panels, conversely, consist of homogeneous materials throughout their entire thickness, such as steel, aluminum, composite materials, or engineered wood products. These panels rely on material density and thickness to achieve required strength characteristics. The uniform material distribution provides predictable mechanical properties and simplified stress analysis calculations. However, this approach typically results in significantly higher weight and material costs compared to equivalent-strength honeycomb alternatives. Manufacturing solid panels involves conventional forming, machining, or molding processes that are well-established in most industrial facilities.

The cellular structure of honeycomb panels creates unique mechanical properties that differ substantially from solid panel behavior. These panels exhibit excellent stiffness-to-weight ratios, often exceeding solid panels by factors of three to five in comparable applications. The honeycomb core provides outstanding resistance to panel buckling and maintains dimensional stability under varying load conditions. Additionally, the air spaces within the cellular structure contribute to superior thermal and acoustic insulation properties, making them valuable for applications requiring environmental control.

Solid panels offer more predictable and isotropic material properties, meaning their strength characteristics remain consistent in all directions. This uniformity simplifies structural calculations and allows engineers to apply standard design methodologies with confidence. The continuous material structure provides excellent resistance to point loads and impact damage, particularly important in heavy-duty industrial applications. Furthermore, solid panels typically demonstrate superior fire resistance and can withstand extreme environmental conditions without compromising structural integrity over extended periods.

Weight reduction represents one of the most significant advantages of honeycomb panels over traditional solid alternatives. Typical weight savings range from 60% to 80% while maintaining comparable or superior structural performance. This dramatic weight reduction directly translates to reduced foundation requirements, lower transportation costs, and simplified installation procedures. In aerospace applications, every pound saved in structural components allows for increased payload capacity or extended range capabilities. Similarly, automotive manufacturers utilize lightweight honeycomb panels to improve fuel efficiency while meeting stringent safety requirements.

The weight efficiency of honeycomb panels becomes particularly advantageous in large-scale construction projects where cumulative weight savings can significantly reduce overall structural loads. Building designers can specify smaller support members, reduce foundation requirements, and optimize structural systems when incorporating lightweight panel solutions. However, engineers must carefully consider the trade-offs between weight savings and other performance requirements such as impact resistance, durability, and maintenance accessibility in their specific applications.

Honeycomb panels excel in applications requiring high bending stiffness and distributed load resistance. The sandwich construction effectively separates face sheets, creating a high moment of inertia that resists flexural deformation. This characteristic makes them ideal for floor systems, roof decking, and wall panels in commercial construction. The cellular core distributes point loads across multiple cells, preventing localized failure and maintaining overall panel integrity under varying load conditions. However, honeycomb panels may be more susceptible to damage from concentrated loads or sharp impacts that can crush individual cells.

Solid panels demonstrate superior performance under concentrated loads and impact conditions due to their continuous material structure. They can withstand heavy equipment loads, repeated impact forces, and harsh environmental conditions without experiencing the localized failures that might affect honeycomb structures. This robustness makes solid panels preferred choices for industrial flooring, heavy machinery foundations, and applications where long-term durability under severe conditions is paramount. The uniform load distribution characteristics of solid panels also simplify connection details and structural interfaces with other building components.

The initial cost comparison between honeycomb panels and solid panels involves multiple factors beyond basic material prices. Honeycomb panels typically command higher unit costs due to specialized manufacturing processes and advanced materials used in their construction. However, the reduced weight often translates to lower transportation and installation costs, particularly for large projects or remote locations. The simplified structural requirements resulting from weight reduction can also decrease overall project costs through reduced foundation work and smaller support members.

Solid panels generally offer lower initial material costs and utilize familiar construction techniques that most contractors can implement without specialized training or equipment. The widespread availability of solid panel materials and standardized installation procedures contribute to competitive pricing in most markets. Additionally, solid panels often require less specialized handling and storage procedures, reducing logistics costs and potential damage during transportation. However, the increased weight may necessitate larger structural members and more robust foundation systems, potentially offsetting initial material savings.

Lifecycle cost analysis reveals important economic differences between honeycomb and solid panel systems. Honeycomb panels often provide superior energy efficiency due to their inherent insulation properties, reducing heating and cooling costs over the building's operational life. The lightweight nature also reduces seismic loads on structures, potentially lowering insurance costs and improving safety factors. Maintenance requirements for honeycomb panels are typically minimal, though repairs can be more complex when damage occurs to the cellular structure.

Solid panels may offer advantages in maintenance accessibility and repair procedures, as damaged sections can often be patched or replaced using conventional construction techniques. The robust nature of solid panels typically results in longer service life under harsh conditions, making them cost-effective choices for industrial applications with demanding operational requirements. However, the higher weight and thermal conductivity of solid panels may result in increased operational costs over time, particularly in climate-controlled environments or structures subject to frequent seismic activity.

In commercial construction, honeycomb panels have gained popularity for curtain wall systems, roof decking, and interior partition walls where weight reduction and thermal performance are priorities. The excellent strength-to-weight ratio makes them ideal for spanning large distances without intermediate support, creating more flexible interior spaces. Their inherent insulation properties contribute to building energy efficiency while the smooth face sheets provide attractive finished surfaces that may eliminate the need for additional cladding materials.

Industrial facilities often benefit from solid panels in areas subject to heavy equipment loads, chemical exposure, or extreme temperatures. Manufacturing floors, equipment foundations, and blast-resistant walls typically require the robust characteristics that solid panels provide. The ability to machine solid panels for precise fitting and the compatibility with standard fastening systems make them practical choices for complex industrial installations. However, some industrial applications, such as clean rooms or refrigerated facilities, may favor honeycomb panels for their superior insulation and contamination control properties.

The aerospace industry extensively utilizes honeycomb panels for aircraft interior panels, cargo bay floors, and secondary structural components where weight reduction directly impacts fuel efficiency and payload capacity. The excellent vibration damping characteristics of honeycomb structures contribute to passenger comfort and equipment protection. Advanced honeycomb panels with carbon fiber face sheets provide exceptional strength while maintaining minimum weight, essential for high-performance aircraft applications.

Automotive manufacturers increasingly incorporate honeycomb panels in vehicle floors, headliners, and body panels to meet fuel efficiency regulations while maintaining safety standards. The energy absorption characteristics of honeycomb structures provide valuable crash protection features. However, critical safety components and high-stress areas may still require solid panel construction to ensure reliable performance under extreme conditions. The choice between honeycomb and solid panels often depends on specific performance requirements, manufacturing constraints, and cost targets for each vehicle model.

Installing honeycomb panels requires careful attention to edge sealing and connection details to prevent moisture infiltration and maintain structural integrity. Specialized fasteners and sealants designed for sandwich panel construction ensure proper load transfer and weather resistance. The lightweight nature simplifies handling and positioning, often allowing installation with smaller equipment and fewer workers. However, installers must understand the unique characteristics of honeycomb panels to avoid damage during construction and ensure proper performance.

Solid panel installation follows conventional construction practices familiar to most contractors, utilizing standard fasteners, connections, and sealing methods. The robust nature of solid panels tolerates minor installation errors better than honeycomb alternatives, reducing the risk of damage during construction. However, the increased weight may require larger cranes, additional temporary support, and more workers for safe installation. The familiar installation procedures often result in faster project completion and reduced training requirements for construction crews.

Honeycomb panels require minimal routine maintenance but may need specialized repair procedures when damage occurs. Small punctures or edge damage can compromise the cellular structure, potentially allowing moisture infiltration that could cause delamination or core degradation. Repair techniques often involve removing damaged sections and bonding in replacement panels using structural adhesives. Preventive maintenance focuses on maintaining edge seals and surface coatings to protect the internal structure from environmental exposure.

Solid panels typically offer simpler maintenance and repair procedures using conventional construction techniques. Damaged areas can often be patched, welded, or mechanically fastened without specialized materials or procedures. The uniform material structure allows for partial repairs that maintain structural continuity and appearance. However, solid panels may require more frequent maintenance of protective coatings and may be more susceptible to corrosion or degradation in harsh environments, particularly when protective systems fail.

Honeycomb panels offer superior strength-to-weight ratios, typically providing 60-80% weight reduction while maintaining comparable structural performance. The cellular core structure distributes loads effectively, resists buckling, and provides excellent bending stiffness. Additionally, the inherent insulation properties and vibration damping characteristics make honeycomb panels advantageous for applications requiring environmental control or noise reduction.

Solid panels are preferred in applications requiring resistance to concentrated loads, impact damage, or extreme environmental conditions. Industrial flooring, heavy equipment foundations, blast-resistant structures, and areas subject to chemical exposure typically benefit from solid panel construction. The predictable material properties and simplified repair procedures also make solid panels suitable for critical infrastructure applications where reliability is paramount.

Honeycomb panels typically have higher initial material costs due to specialized manufacturing processes, but often provide overall project savings through reduced transportation, installation, and structural support requirements. Solid panels offer lower material costs and utilize familiar construction techniques, but may require more robust support systems due to increased weight. Total project costs depend on specific application requirements, project scale, and local material availability.

Honeycomb panels require protection of edge seals and face sheets to prevent moisture infiltration and core damage, but generally need minimal routine maintenance. Solid panels may require more frequent protective coating maintenance but offer simpler repair procedures using conventional construction techniques. The choice depends on maintenance capabilities, environmental exposure, and long-term operational requirements for the specific application.