Modern construction and engineering projects demand materials that combine versatility, performance, and aesthetic appeal. Composite panels have emerged as the preferred solution for architects, engineers, and designers who require customizable building materials that deliver exceptional structural integrity without compromising design flexibility. These innovative building components offer unparalleled advantages in weight reduction, thermal efficiency, and design adaptability, making them indispensable for contemporary construction applications.

The construction industry has witnessed a significant shift toward materials that provide superior performance characteristics while maintaining cost-effectiveness. Engineers and architects increasingly recognize that traditional building materials often fall short of meeting complex project requirements, particularly when custom specifications are essential. This evolution has positioned composite panels as the material of choice for projects requiring precise engineering specifications, aesthetic flexibility, and long-term durability.

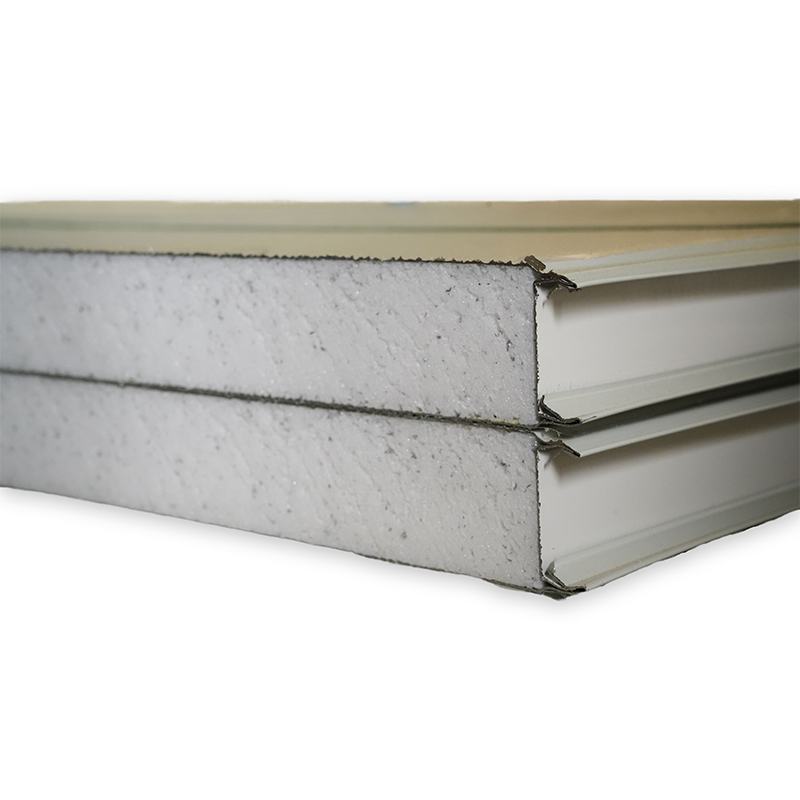

Composite panels deliver exceptional structural performance through their multi-layered construction design. The sandwich panel configuration combines lightweight core materials with robust outer layers, creating a structural system that maximizes strength-to-weight ratios. This engineering approach enables architects to design larger spans with reduced structural support requirements, opening new possibilities for creative architectural solutions.

The load distribution characteristics of composite panels surpass traditional building materials in numerous applications. Engineers can specify thinner panel configurations while maintaining required load-bearing capacities, resulting in reduced overall building weight and foundation requirements. This structural efficiency translates directly into cost savings and enhanced design flexibility for complex engineering projects.

Advanced manufacturing techniques ensure consistent structural properties throughout each panel, eliminating the variability often encountered with conventional building materials. Quality control processes verify that each composite panel meets precise engineering specifications, providing engineers with reliable performance data for structural calculations and safety factor determinations.

The insulation properties of composite panels significantly exceed those of traditional building materials, making them ideal for projects requiring specific thermal performance criteria. The core materials used in these panels provide exceptional resistance to heat transfer, reducing energy consumption and enhancing occupant comfort in finished structures.

Engineers can select from various core materials to achieve specific thermal resistance values, enabling precise control over building envelope performance. This customization capability ensures that projects meet stringent energy efficiency requirements while maintaining structural integrity and aesthetic appeal. The continuous insulation provided by composite panels eliminates thermal bridging concerns common with conventional construction methods.

Temperature stability across diverse climate conditions makes composite panels suitable for projects in extreme environments. The materials maintain their structural and thermal properties across wide temperature ranges, ensuring consistent performance throughout the building's service life. This reliability factor is crucial for engineering projects in challenging geographical locations or specialized applications.

Manufacturing flexibility allows composite panels to be produced in virtually any dimension required for specific project applications. Engineers can specify exact panel sizes, thicknesses, and configurations to meet unique design requirements without the constraints imposed by standard building materials. This customization capability eliminates the need for field modifications and reduces installation complexity.

Custom core configurations enable engineers to optimize panels for specific performance requirements, whether prioritizing thermal insulation, structural strength, fire resistance, or acoustic properties. The ability to specify core materials and densities ensures that each panel delivers optimal performance for its intended application while maintaining compatibility with overall project requirements.

Surface preparation options provide additional customization opportunities for projects requiring specific aesthetic or functional characteristics. Engineers can specify surface textures, coatings, or treatments that enhance durability, appearance, or specialized performance attributes. This level of customization ensures seamless integration with architectural design concepts and functional requirements.

The design versatility of composite panels enables architects to achieve complex aesthetic goals without compromising structural performance. Various surface finishes, colors, and textures can be applied during manufacturing, creating panels that serve both structural and decorative functions. This dual capability simplifies construction processes and reduces material costs for projects requiring both structural and aesthetic elements.

Advanced surface treatment technologies allow composite panels to mimic traditional building materials while providing superior performance characteristics. Architects can specify wood grain textures, stone appearances, or metallic finishes that complement design themes while delivering the structural and thermal benefits of modern composite construction.

Integration with building information modeling systems enables precise visualization of how composite panels will appear in finished structures. This capability allows design teams to evaluate aesthetic options and make informed decisions before manufacturing begins, reducing project risks and ensuring design intent is achieved in the final construction.

The modular nature of composite panels significantly reduces construction timelines compared to traditional building methods. Prefabricated panels arrive on-site ready for installation, eliminating time-consuming field assembly processes and reducing labor requirements. This efficiency advantage is particularly valuable for projects with aggressive completion schedules or those in remote locations where labor availability is limited.

Connection systems designed specifically for composite panels ensure rapid and secure installation while maintaining structural integrity. Engineered connection details eliminate guesswork and provide consistent installation quality across entire projects. These standardized approaches reduce the skill level required for installation while ensuring that performance specifications are met.

Quality control measures implemented during manufacturing eliminate many field inspection requirements, accelerating approval processes and reducing project delays. Pre-manufactured panels undergo rigorous testing and quality verification before delivery, providing engineers with confidence in material performance and reducing on-site verification requirements.

Installation of composite panels is less dependent on favorable weather conditions compared to traditional construction methods. The panels can be installed in various weather conditions without compromising performance or installation quality, reducing project delays caused by weather-related interruptions. This advantage is particularly valuable for projects in regions with challenging seasonal weather patterns.

The lightweight characteristics of composite panels enable installation using smaller crane equipment and reduced crew sizes, providing flexibility in construction logistics and reducing weather-related equipment constraints. This operational efficiency contributes to more predictable project schedules and reduced construction costs.

Moisture resistance properties ensure that panels maintain their structural and thermal properties even if exposed to precipitation during installation. This durability eliminates concerns about weather-related damage during construction and provides confidence in long-term performance regardless of installation conditions.

While composite panels may require higher initial material costs compared to some traditional alternatives, the total project cost often favors composite panel solutions when installation efficiency and performance benefits are considered. Reduced labor requirements, faster installation timelines, and eliminated secondary operations contribute to overall cost savings that offset higher material expenses.

The precision manufacturing of composite panels reduces material waste and eliminates the need for field modifications, contributing to cost predictability and budget control. Engineers can accurately estimate material quantities and installation costs, reducing project financial risks and enabling more competitive bidding processes.

Integration of multiple building functions into single panel systems eliminates the need for separate structural, insulation, and finish materials, simplifying procurement processes and reducing overall material costs. This system approach provides cost transparency and simplifies project budgeting and cost control processes.

The superior insulation properties of composite panels directly translate into reduced operational energy costs throughout the building's service life. Lower heating and cooling requirements result in significant utility savings that accumulate over time, providing excellent return on investment for building owners and operators.

Maintenance requirements for composite panels are typically minimal compared to traditional building systems, reducing long-term operational costs and extending service life. The integrated construction approach eliminates many maintenance-prone interfaces and connections common in conventional building assemblies.

Durability characteristics ensure that composite panels maintain their performance properties over extended service periods, reducing replacement costs and minimizing building lifecycle expenses. This longevity advantage is particularly valuable for projects where accessibility for maintenance and replacement is limited or expensive.

Composite panels contribute to sustainable construction practices through efficient material utilization and reduced resource consumption. The manufacturing process optimizes material usage, minimizing waste and reducing the environmental impact associated with material production and transportation. This efficiency aligns with green building initiatives and environmental certification requirements.

The lightweight characteristics of composite panels reduce transportation fuel consumption and associated emissions during project delivery. Fewer transportation trips are required to deliver equivalent building envelope area compared to traditional materials, contributing to reduced project carbon footprints and environmental impact.

Recyclability considerations in composite panel manufacturing ensure that materials can be recovered and reused at the end of building service life. This circular economy approach reduces landfill impacts and supports sustainable building practices increasingly required by building codes and certification programs.

The thermal performance advantages of composite panels directly contribute to building energy efficiency and reduced operational emissions. Superior insulation properties minimize heating and cooling energy requirements, supporting net-zero energy building goals and reducing long-term environmental impacts.

Integration with renewable energy systems is facilitated by the structural capabilities and installation flexibility of composite panels. Solar panel mounting systems, green roof applications, and other sustainable building technologies can be easily integrated with composite panel building envelopes, enhancing overall environmental performance.

Lifecycle assessment studies consistently demonstrate favorable environmental profiles for composite panels compared to traditional building materials when total environmental impact is considered. These assessments account for manufacturing, transportation, installation, operational, and end-of-life impacts, providing comprehensive environmental performance data.

Composite panels excel in commercial and industrial applications where rapid construction, thermal performance, and cost-effectiveness are primary concerns. Warehouses, manufacturing facilities, and distribution centers benefit from the large span capabilities and thermal efficiency of composite panel construction, creating functional spaces that meet operational requirements while controlling construction and operational costs.

The clean appearance and low maintenance requirements of composite panels make them ideal for commercial applications where aesthetic appeal and operational efficiency are important considerations. Office buildings, retail facilities, and hospitality projects can achieve sophisticated appearances while benefiting from the performance advantages of composite construction.

Specialized industrial applications requiring controlled environments, such as food processing facilities, pharmaceutical manufacturing, and data centers, benefit from the precise thermal and moisture control capabilities of composite panels. These applications demand consistent performance and reliability that composite panels deliver effectively.

Educational facilities, healthcare buildings, and government structures often require building systems that provide long-term durability, energy efficiency, and minimal maintenance requirements. Composite panels address these institutional needs while providing design flexibility for complex architectural requirements and specialized functional needs.

Emergency response facilities, military installations, and critical infrastructure projects benefit from the rapid deployment capabilities and structural reliability of composite panels. These applications often require construction in challenging conditions or remote locations where conventional building methods are impractical or inefficient.

Research facilities, laboratories, and specialized institutional buildings requiring controlled environments benefit from the precision and consistency of composite panel performance. The ability to customize thermal, acoustic, and structural properties ensures that specialized requirements are met effectively.

Composite panels are typically available in thicknesses ranging from 50mm to 300mm, with custom thicknesses possible for specialized applications. The thickness selection depends on structural requirements, thermal performance goals, and architectural considerations. Engineers can specify exact thicknesses to optimize performance for specific project requirements while maintaining cost-effectiveness.

Composite panels can be manufactured with fire-resistant core materials and coatings to meet specific fire safety requirements and building code compliance. Various fire rating classifications are achievable through appropriate material selection and design. The panels can be engineered to provide fire resistance ratings comparable to or exceeding traditional building materials while maintaining other performance advantages.

Custom composite panel lead times typically range from 4 to 8 weeks depending on project complexity, customization requirements, and manufacturing capacity. Standard configurations may be available in shorter timeframes, while highly customized panels requiring specialized materials or finishes may require extended manufacturing periods. Early engagement with manufacturers helps optimize lead times and ensure project schedule compliance.

Composite panels can be engineered and tested to meet seismic and wind load requirements for various geographic locations and building classifications. Proper engineering analysis and connection design ensure that panels perform safely under extreme loading conditions. The lightweight characteristics of composite panels can actually provide advantages in seismic applications by reducing overall building mass and seismic forces.