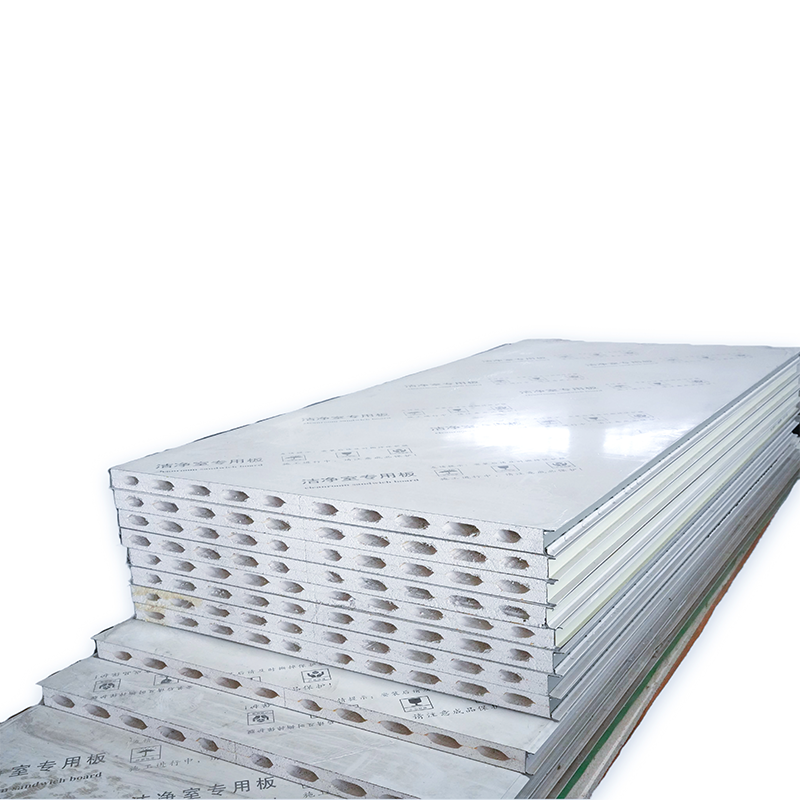

ផ្ទាំងស៊ុម បានក្លាយជាមូលដ្ឋាគ្រឹះសំណង់ទំនើបកាន់តែច្រើនដោយសារវាអាចបញ្ចូលគ្នាបាននូវភាពរឹងមាំ ការពារកំដៅ និងគុណសម្បត្តិស្រាលនៅក្នុងវត្ថុធាតុតែមួយ។ អ្នកសាងសង់ចូលចិត្តវិធីដែលផ្ទៃខាងក្រឡាចត្រង់ទាំងនេះធ្វើឱ្យដំណើរការដំឡើងកាន់តែរហ័ស ខណៈពេលផ្តល់នូវស្ថេរភាពសាងសង់ដ៏អស្ចារ្យ។ ផ្ទៃខាងក្រឡាចត្រង់ (Sandwich Panel) មានសមាសធាតុផ្សំពីសន្លឹកលោហៈរឹងមាំពីរសន្លឹក ដែលភ្ជាប់ជាមួយនឹងសន្លឹកក្នុងដែលមានសីតុណ្ហភាពថេរ ដែលភាគច្រើនផលិតពីប៉ូលីយៀរេត (polyurethane) សំបករ៉ែ ឬប៉ូលីស្ទីរ៉េន (polystyrene) ខុសពីវត្ថុធាតុសាងសង់ប្រពៃណី។ សំណង់នេះផ្តល់នូវសមត្ថភាពយន្តកម្មខ្ពស់ ដោយការប្រើប្រាស់វត្ថុធាតុអប្បបរមា ដែលធ្វើឱ្យវាមានតម្លៃសមរម្យ និងការទទួលខុសត្រូវលើបរិស្ថាន។ ផ្ទៃខាងក្រឡាចត្រង់ត្រូវបានរចនាមុន ដែលកាត់បន្ថយការចំណាយលើកម្មករ បំបើនដំណើរការ និងធានានូវគុណភាពនៅក្នុងស្ថានការណ៍សាងសង់ផ្សេងៗ។ មិនថាវាត្រូវបានប្រើសម្រាប់ដំបើល ក្រឡាផ្ទៃជញ្ជាំង ឬបែងចែកទំហំនោះទេ ផ្ទៃខាងក្រឡាចត្រង់ (Sandwich Panel) តែងតែផ្តល់នូវសមត្ថភាព និងភាពទាក់ទាញផ្នែកទស្សន៍។ សម្រាប់អ្នកសាងសង់ដែលផ្តោតលើល្បឿន ភាពជឿទុកចិត្តបាន និងការបញ្ញើសន្សំរយៈពេលវែង វានៅតែជាវត្ថុធាតុដែលមានគុណភាពខ្ពស់បំផុត។

មួយក្នុងចំណោមគុណសម្បត្តិទាក់ទាញបំផុតនៃបន្ទះ Sandwich គឺរចនាសម្ព័ន្ធរបស់វាមានទម្ងន់ស្រាល ដែលមិនប៉ះពាល់ដល់សុវត្ថិភាពសំណង់។ តុល្យភាពនេះអាចជួយអ្នកសាងសង់កាត់បន្ថយបន្ទុកលើសំណង់បង្កាន់ដ្ឋាន និងមូលដ្ឋាន ដែលនាំឱ្យដំណោះស្រាយវិស្វកម្មមានប្រសិទ្ធភាពខ្ពស់។ ជាពិសេសតំបន់មានសកលភាពខ្លាំង ឬតំបន់មានព្យុះខ្លាំង ការប្រើប្រាស់បន្ទះ Sandwich អាចចូលរួមការពារសុវត្ថិភាពអគារទាំងមូល ដោយកាត់បន្ថយម៉ាស់ដោយមិនចាំបាច់ធ្វើឱ្យកំណប់បាក់។ ការដឹកជញ្ជូន និងការគ្រប់គ្រងនៅតំបន់សំណង់ក៏កាន់តែងាយស្រួលឡើង ដែលអនុញ្ញាតឱ្យក្រុមការងារសាងសង់ធ្វើការប្រកបដោយប្រសិទ្ធភាព និងកាត់បន្ថយហានិភ័យ។ បន្ទះទាំងនោះអាចកាត់ និងកែសម្រួលបានយ៉ាងងាយស្រួល ដើម្បីឱ្យសមស្របនឹងរចនាប័ទ្មស្មុគស្មាញ ផ្ដល់ឱ្យអ្នកសាងសង់នូវសេរីភាពក្នុងការច្នៃប្រឌិតដោយគ្មានការរើសអើងសុវត្ថិភាព។ រចនាសម្ព័ន្ធបែប Sandwich ផ្ដល់នូវភាពរឹងមាំធម្មជាតិ ដោយសារស្រទាប់ខាងក្រៅប្រឆាំងនឹងកម្លាំងទាញ ខណៈដែលស្នូលទប់ទល់នឹងកម្លាំងកាត់។ នេះប្រៀបបន្ទះ Sandwich ទៅជាដំណោះស្រាយប្រកបដោយប្រសិទ្ធភាពសម្រាប់គ្រប់គ្រងអ្វីៗទាំងអស់ ពីសណ្ឋាគារបណ្ដោះអាសន្ន រហូតដល់ស្ថានភាពឧស្សាហកម្ម

វិស័យឧស្សាហកម្ម និងពាណិជ្ជកម្មបានស្គាល់យូរមកហើយនូវអត្ថប្រយោជន៍នៃការប្រើប្រាស់ផ្ទៃខាងក្រៅ (Sandwich Panel) ក្នុងកម្មវិធីសាងសង់ និងបែបបទមើលទេសភាពយ៉ាងច្រើន។ អគារផ្ទុកទំនិញ ទីស្តុកដឹកជញ្ជូន និងបន្ទប់ថវីកុំព្យូទ័រទទួលបានត្ថប្រយោជន៍យ៉ាងខ្លាំងពីសមត្ថភាពរបស់វាក្នុងការការពារកំដៅ និងដំឡើងយ៉ាងរហ័ស។ នៅក្នុងបរិយាកាសបែបនេះ ដែលពេលវេលាមានតម្លៃថ្លៃ និងការគ្រប់គ្រងអាកាសធាតុគឺជាកត្តាសំខាន់ ផ្ទៃខាងក្រៅ (Sandwich Panel) ធ្វើការកាត់បន្ថយការចំណាយថាមពល ខណៈពេលដែលបញ្រ្ជាប់ដំណើរការសាងសង់។ វាក៏ធានានូវការទប់ទល់នឹងភ្លើងបានខ្ពស់ នៅពេលប្រើប្រាស់សរសៃរ៉ែ (mineral wool cores) ដែលធ្វើឱ្យវាសមស្របសម្រាប់អគារដែលមានបទបញ្ញត្តិសុវត្ថិភាពតឹងរ៉ឹង។ អ្នកសាងសង់ដែលកំពុងធ្វើការលើអាគារផ្សារទំនើប រោងចក្រ ឬបន្ទប់បង្ហាញ ប្រើប្រាស់សម្ភារៈនេះសម្រាប់ជញ្ជាំងខាងក្រៅ និងប្រព័ន្ធបំពែក ដើម្បីបង្កើនប្រសិទ្ធភាពថាមពល ខណៈពេលដែលផ្ដល់នូវរូបរាងស្រស់ស្អាត និងសុទ្ធាសាស្ត្រ។ ភាពបត់បែនរបស់ផ្ទៃខាងក្រៅ (Sandwich Panel) អនុញ្ញាតឱ្យការពន្លូត ឬជួសជុលក្នុងអនាគតកើតឡើងយ៉ាងងាយស្រួល ដោយផ្ដល់នូវភាពបត់បែនក្នុងការរចនា នៅក្នុងវិស័យមួយដែលភាពបត់បែនគឺជាគន្លឹះ។

ទោះបីជាមានការសន្មតថា បន្ទះស័ង់វិច (Sandwich Panel) ត្រូវបានគេប្រើប្រាស់ជាទូទៅនៅក្នុងវិស័យពាណិជ្ជកម្មក៏ដោយ ប៉ុន្តែវាកំពុងទទួលបានការពេញនិយមកាន់តែច្រើននៅក្នុងវិស័យសំណង់ផ្ទះសម្បែង ជាពិសេសសម្រាប់ផ្ទះដែលផលិតជាមុន ផ្នែកបន្ថែម និងផ្ទះសន្សំថាមពល។ អ្នកសាងសង់ដែលមានគោលបំណងផ្តល់ជូននូវដំណោះស្រាយផ្ទះសម្បែងទំនើប និងប្រកបដោយភាពប្រុងប្រយ័ត្នចំពោះបរិស្ថាន បានប្រើបន្ទះស័ង់វិច (Sandwich Panel) ដោយសារគុណសម្បត្តិកក់កំដៅដ៏ល្អរបស់វា ដែលជួយកាត់បន្ថយតម្រូវការក្នុងការត្រជាក់ និងការបំបែកកំដៅ។ បន្ថែមពីលើនេះ រូបរាងរលូន និងការមានវត្តមាននៅក្នុងពណ៌ និងអត្ថបទផ្សេងៗ ក៏ជួយគាំទ្រដល់សោភ័ណវិទ្យាស្ថាបត្យកម្មទំនើបផងដែរ។ នៅតំបន់ទីក្រុងដែលមានប្រជាជនកំពុងកើនឡើង ល្បឿននៃការសាងសង់ដែលផ្តល់ដោយបន្ទះស័ង់វិច (Sandwich Panel) គឺពិតជាមានប្រយោជន៍។ វាអនុញ្ញាតឱ្យម្ចាស់ផ្ទះអាចផ្លាស់ទៅរស់នៅបានភ្លាមៗ និងទទួលបាននូវស្ថានភាពរស់នៅយ៉ាងស្រួល ដោយការថែទាំតិចតួច។ លើសពីនេះ ភាពធន់នឹងសត្វល្មុង មេរោគ និងសំណើម ធានានូវភាពធន់យូរអង្វែងនៅក្នុងអាកាសធាតុផ្សេងៗ។ នៅពេលដែលការគ្រោងទីក្រុងកំពុងវិវឌ្ឍន៍ បន្ទះស័ង់វិច (Sandwich Panel) ក៏កំពុងប៉ាន់ទៅរកដំណោះស្រាយនាពេលអនាគត ដែលសម្របខ្លួនទៅនឹងទាំងបរិស្ថាន និងគោលបំណងប្រតិបត្តិការណ៍។

លក្ខណៈពិសេសមួយនៃបន្ទប់ Sandwich Panel គឺការកកស្ទះកម្តៅដ៏អស្ចារ្យរបស់វា ដែលមានតួនាទីសំខាន់ក្នុងការបង្កើនប្រសិទ្ធភាពថាមពលលើគ្រប់ប្រភេទអគារ។ កណ្តាលកំដៅកាត់បន្ថយការផ្ទេរកំដៅយ៉ាងសំខាន់ ដោយរក្សាសំដៅក្នុងផ្ទះដោយមានការពឹងផ្អែកយ៉ាងតិចលើប្រព័ន្ធ HVAC ។ នេះមានតម្លៃជាពិសេសនៅក្នុងតំបន់ដែលមានអាកាសធាតុធ្ងន់ធ្ងរ ដែលលទ្ធផលនៃការប្រើប្រាស់កម្តៅបានបកស្រាយដោយផ្ទាល់ទៅក្នុងការថយថ្លៃ និងក្តីសុខ។ អ្នកសាងសង់ទទួលបានផលប្រយោជន៍ពីតម្លៃ R ដែលអាចព្យាករណ៍បាន និងឱកាសដើម្បីបំពេញ ឬលើសកូដអគ្គិសនីនៃអគារ។ ការប្រើប្រាស់ថាមពលថយចុះក៏គាំទ្រគោលដៅអភិវឌ្ឍន៍ប្រកបដោយចីរភាពពិភពលោក ដោយកាត់បន្ថយការកែច្នៃកាបូនរបស់អគារ។ ផ្ទាំង Sandwich ជួយរក្សាសភាពប្រកបដោយអាកាសធាតុក្នុងផ្ទះ, ចៀសវាងស្លាបព្រែកក្តៅនិងធានាថាលទ្ធផលថាមពលសមស្របនៅលើផ្ទៃទាំងអស់។ ភាពជឿជាក់នេះធ្វើឱ្យវាជាជម្រើសដែលពេញចិត្តនៅក្នុងការរចនាអគារដែលមិនប្រើប្រាស់ទឹក និងរចនាសម្ព័ន្ធដែលយល់ដឹងអំពីថាមពល។

ឧស្សាហកម្មសំណង់បច្ចុប្បន្នកំពុងប្រឈមនឹងស្តង់ដារនៃការអភិវឌ្ឍន៍ប្រកបដោយនិរន្តរភាពកាន់តែខ្លាំងឡើង ហើយផ្ទៃក្រឡាផ្សំ (Sandwich Panel) ក៏បានឆ្លើយតបទៅនឹងសំណេះសំណាលនោះដោយការមានវត្តមានរបស់វាដែលប្រកបដោយការទទួលខុសត្រូវចំពោះបរិស្ថាន។ អ្នកផលិតជាច្រើននាក់កំពុងផ្តល់ជូននូវផ្ទៃក្រឡាដែលមានផ្ទុកធាតុឡើងវិញ (recycled content) និងដំណើរការផលិតកម្មដែលមានផលប៉ះពាល់បរិស្ថានទាប។ លើសពីនេះទៀត ការសន្សំសំចៃថាមពលដែលកើតឡើងក្នុងអំឡុងពេលអាគារត្រូវបានប្រើប្រាស់ ក៏លើសពីតម្លៃដើមនៃវត្ថុធាតុផ្សំដែលបានចំណាយក្នុងដំណាក់កាលដំបូង។ អ្នកសាងសង់ក៏អាចជ្រើសរើសវត្ថុធាតុផ្នែកខាងក្នុងបានយោងតាមគោលដៅគម្រោងជាក់លាក់ ដោយផ្តោតលើការទប់ទល់ភ្លើង ការការពារសំឡេង ឬផលប៉ះពាល់បរិស្ថាន។ ផ្ទៃក្រឡាផ្សំ (Sandwich Panel) ក៏បង្កើតកាកសំណល់បានតិចជាងបេតុង ឬឥដ្ឋ ហើយវាក៏ងាយស្រួលក្នុងការកែច្នៃឡើងវិញនៅចុងបញ្ចប់នៃវដ្តជីវិតរបស់វា។ ការកាត់បន្ថយការបញ្ចេញឧស្ម័នដែលកើតឡើងដោយសារតែពេលវេលាសាងសង់ដែលលឿនជាង និងការធ្វើដំណើររបស់យានយន្តបានកាត់បន្ថយក៏ជាកត្តាមួយដែលរួមចំណែកដល់ការបន្ថយផ្នែកបរិស្ថាន។ អ្នកសាងសង់ដែលកំពុងស្វែងរកវិធីបំពេញតាមស្តង់ដារវិញ្ញាបនបត្របៃតង (LEED) ឬស្តង់ដារផ្សេងទៀត ក៏អាចរកបាននូវផ្ទៃក្រឡាផ្សំ (Sandwich Panel) ជាផ្នែកមួយដែលមានប្រសិទ្ធភាពសម្រាប់ប្រើក្នុងឧបករណ៍របស់ពួកគេ។

ពេលវេលាគឺជាធនធានដ៏មានតម្លៃក្នុងគ្រប់គម្រោងសំណង់ទាំងអស់ ហើយផ្ទៃខាងក្រៅប្រភេទ Sandwich Panel អាចកាត់បន្ថយការដំឡើងបានយ៉ាងឆាប់រហ័ស។ ដោយសារវាមានសភាពជាមុននិងមានទម្រង់ម៉ូឌុល ផ្ទៃខាងក្រៅទាំងនេះមកដល់តំបន់សំណង់ក្នុងស្ថានភាពត្រៀមខាងដំឡើង ដែលធ្វើឱ្យការប្រើប្រាស់ឧបករណ៍ស្មុគស្មាញមានកម្រិត និងកាត់បន្ថយការខំញើស។ អ្នកសាងសង់អាចបញ្ចប់ផ្នែកធំៗនៃអគារក្នុងរយៈពេលខ្លីបើធៀបទៅនឹងវិធីសាស្ត្រធម្មតា។ ការដំឡើងលឿននេះមិនត្រឹមតែកាត់បន្ថយពេលវេលាគម្រោងនោះទេ ថែមទាំងកាត់បន្ថយការចំណាយបន្ថែមទៀតផង ដូចជាការអនុវត្តន៍តាមដាន និងសំណង់បណ្ដោះអាសន្ន។ ស្ថេរភាពទំហំរបស់ផ្ទៃខាងក្រៅប្រភេទ Sandwich Panel ធានាអំពីការតម្រឹមបានល្អឥតខ្ចោះ ដែលធ្វើឱ្យការភ្ជាប់ជាមួយផ្ទះកញ្ចក់ ទ្វារ និងប្រព័ន្ធផ្សព្វផ្សាយកាន់តែងាយស្រួល។ សូម្បីតែក្នុងស្ថានភាពអាកាសធាតុមិនអំណោយផល ការដំឡើងក៏អាចបន្តបានដោយការយឺតយ៉ាវតិចតួច ដោយសារលក្ខណៈទប់ទឹក និងមិនខូចទ្រង់ទ្រាយរបស់វា។ ប្រសិទ្ធភាពនៃផ្ទៃខាងក្រៅប្រភេទ Sandwich Panel សមនឹងការអភិវឌ្ឍន៍យ៉ាងរហ័សដោយមិនប៉ះពាល់គុណភាពនោះទេ។

អ្នកសាងសង់ និងម្ចាស់អចលនទ្រព្យជាច្រើន ពិតជាចូលចិត្តនូវគ្របផ្ទៃពីរ (Sandwich Panel) ដែលមានតម្រូវការថែទាំទាប។ ស្រទាប់ការពារខាងក្រៅត្រូវបានរចនាឡើងដើម្បីឱ្យអាចទប់ទល់នឹងកាំរស្មី UV កំហាយបំពុល និងការប៉ះទង្គិចយន្តសាស្ត្រ ដើម្បីរក្សារូបរាងអាគារឱ្យបានថ្មីជារៀងរហូត។ ខុសពីសម្ភារធាតុបុរាណដែលត្រូវការថែទាំដូចជាការថើបថ្នាំថ្មី ការបិទជីកសោ ឬការបិទខ្ទះ គ្របផ្ទៃពីរ (Sandwich Panel) នឹងរក្សានូវភាពថេរវិនិច្ឆ័យដោយការថែទាំអប្បបរមា។ វាក៏មានភាពធន់នឹងការចិញ្ចៀន ការបំផ្លាញដោយស៊ី និងសត្វល្អិត ដែលធ្វើឱ្យវាកាន់តែមានតម្លៃនៅតំបន់ដែលមានសំណើម ឬតំបន់ឆ្នេរ។ អាយុកាលវែងនៃសម្ភារៈនេះ បង្ហាញពីការរំខានតិចតួចក្នុងអំឡុងពេលនៃអាគារ ដែលធ្វើឱ្យការចំណាយប្រតិបត្តិការថយចុះ និងការបំពេញតម្រូវការអ្នកប្រើប្រាស់កើនឡើង។ ការត្រួតពិនិត្យឱ្យបានទៀងទាត់ និងការសម្អាតសាមញ្ញ គឺជារឿងគ្រប់គ្រាន់ដើម្បីរក្សានូវសមត្ថភាព និងភាពទាក់ទាញ។ ភាពធន់នៃវែងនេះ បញ្ជាក់ពីតម្លៃនៃគ្របផ្ទៃពីរ (Sandwich Panel) ថាជាការវិនិយោគមួយ ដែលផ្តល់នូវលទ្ធផលសាងសង់ដែលមានស្ថេរភាព និងហានិភ័យទាប។

ផ្ទៃកាបូបប្រភេទ Sandwich ផ្តល់នូវភាពច្នៃប្រឌិតដ៏ធំធេងដល់អ្នកសាងសង់ និង អ្នករចនាដែលអាចបំពេញតាមតម្រូវការរចនាស្មុគស្មាញ ដោយមិនប៉ះពាល់ដល់សមត្ថភាពប្រើប្រាស់នៃវា។ ផ្ទៃកាបូបនេះមានសំណាក់ពណ៌ បញ្ចប់ និង សាច់ក្រណាត់ទំនើបជាច្រើនប្រភេទ ដែលអាចកែសម្រួលតាមតម្រូវការផ្នែកប្រើប្រាស់ និង ផ្នែកសិល្បៈ។ មិនថារចនាមានតម្រូវការសម្រាប់ផ្នែកខាងក្រៅមួយពណ៌រលូន ឬ ការតុបតែងបែបសិប្បនិមិត្តឈើទេ ផ្ទៃកាបូបប្រភេទ Sandwich នឹងផ្តល់ជូននូវរចនាបថដ៏ប្រណិត។ ផ្ទៃកាបូបដែលបត់បែនបាន ការដោះស្រាយជ្រុង និង ផ្នែកលម្អិតដែលរួមបញ្ចូលគ្នាសុទ្ធតែអាចសម្រេចបានដោយមានការខ្ជះខ្ជាយតិចតួច និង ការរចនាវិស្វកម្មមានសភាពងាយស្រួល។ អ្នកសាងសង់អាចធ្វើការលើរចនាបថស្ថាបត្យកម្មប្រភេទផ្សេងៗ ពីរចនាសម្ព័ន្ធសាមញ្ញ រហូតដល់ផ្នែកខាងមុខបែបទំនើប។ ដោយសារសមត្ថភាពរបស់វាក្នុងការបញ្ចូលគ្ននូវសមត្ថភាពប្រើប្រាស់ និង សោភណភាព ផ្ទៃកាបូបប្រភេទ Sandwich អាចបំពេញតាមតម្រូវការស្ថាបត្យកម្មទាំងឯកជន និង សាធារណៈ។ វាក៏បើកដំណើរការបែបប្រែ និង ធានានូវស្ថេរភាព និង ប្រសិទ្ធភាព។

នៅក្នុងវិស័យសំណង់បច្ចុប្បន្នដែលការប្រកួតប្រជែងមានកំរិតខ្ពស់ មុខងារត្រូវការរួមផ្សំជាមួយនឹងឥទ្ធិពលផ្នែកទស្សន៍។ ផ្ទាំងសាឡិក (Sandwich Panel) ជួយអ្នកសាងសង់ឲ្យសម្រេចបាននូវតុល្យភាពនេះ ដោយផ្តល់ជូននូវសម្ភារៈមួយដែលមិនត្រឹមតែមានសមត្ថភាពខ្ពស់ ប៉ុន្តែថែមទាំងមានភាពចម្រុះផ្នែករូបរាង។ បន្ទាត់ស្អាត និងផ្ទៃមួយដែលមានសភាពចក្រីក្រិត ធ្វើឱ្យវាកាន់តែឆើតឆាយជាមួយនឹងភាសាស្ថាបត្យកម្មបែបទំនើប ខណៈពេលដែលបច្ចេកវិទ្យាព្រីនជាមុខ អនុញ្ញាតឱ្យផ្ទាំងទាំងនោះបង្ហាញរូបរាងដូចថ្ម ឬ ឈើ ឬគំរូផ្ទាល់ខ្លួន។ អ្នកសាងសង់ដែលកំពុងធ្វើការលើគម្រោងអាគារសន្និសីទ មជ្ឈមណ្ឌលវប្បធម៌ ឬ អាគារលំនៅដ្ឋានប្រណិត ជាទូទៅសុទ្ធតែរកឃើញថា ផ្ទាំងសាឡិក (Sandwich Panel) អាចជួយពួកគេសម្រេចបាននូវរូបរាងប្រណិតដោយគ្មានការចំណាយលើសហេតុ។ ក្រៅពីរូបរាង ការតភ្ជាប់គ្មានសន្លាក់ និងការតំឡើងខ្សែអ៊ីសូឡង់ (insulation) បង្កប់ក្នុងផ្ទាំង បានលើកកម្ពស់នូវភាពស្រួល និងភាពត្រឹមត្រូវផ្នែករចនាសម្ព័ន្ធ។ សមត្ថភាពបែបពីរផ្នែកនេះ ធ្វើឱ្យដំណើរការសំណង់កាន់តែរហ័ស និងបង្កើនគុណភាពលទ្ធផលចុងក្រោយ ដោយបំពេញតាមតម្រូវការបច្ចេកទេស និងការរំពឹងទុករបស់អតិថិជន។

ផ្ទៃកាតពីរជាន់ផ្តល់នូវការការពារកំដៅល្អប្រសើរ មានទម្ងន់ស្រាលប៉ុន្តែមានភាពរឹងមាំ និងដំណើរការតំឡើងបានលឿនជាងវត្ថុធាតុដើមប្រពៃណី។ លក្ខណៈម៉ូឌុលរបស់វាកាត់បន្ថយពេលវេលាសាងសង់ និងកម្លាំងពលកម្ម ខណៈដែលរចនាសម្ព័ន្ធផ្នែកកណ្ដាលរបស់វាផ្តល់នូវប្រសិទ្ធភាពថាមពលកាន់តែប្រសើរ និងភាពធន់ធន់។

បាទ/ចាស៎ ផ្ទៃកាតពីរជាន់កំពុងបានប្រើយ៉ាងទូលំទូលាយក្នុងគម្រោងលំនៅដ្ឋាន ជាពិសេសសម្រាប់ផ្ទះដែលបានសាងជាមុន ផ្នែកបន្ថែម និងរចនាបែបសន្សំសំចៃថាមពល។ វាផ្តល់នូវភាពទាក់ទាញបែបទំនើប ការប្រមូលផ្តុំបានលឿន និងការការពារកំដៅដ៏អស្ចារ្យ ដែលធ្វើឱ្យវាសាកសមសម្រាប់កន្លែងស្នាក់នៅក្នុងតំបន់ទីក្រុង និងកន្លែងដែលមាននិរន្តរភាព។

ផ្ទៃកាតពីរជាន់ត្រូវបានរចនាឡើងដើម្បីឱ្យអាចទប់ទល់នឹងស្ថានភាពបរិស្ថានអាក្រក់ រួមមានភ្លៀងធ្ងន់ៗ បាយញី ខ្យល់ និងកាំរស្មី UV។ ការការពារផ្នែកកណ្ដាលរបស់វាជួយរក្សាសីតុណ្ហភាពខាងក្នុង ខណៈដែលសន្លឹកខាងក្រៅធន់នឹងការដែលប៉ះពាល់ ដែលធ្វើឱ្យវាសាកសមសម្រាប់អាកាសធាតុគ្រប់ប្រភេទ។

បន្ទះសាន់ដ័រ (Sandwich Panels) ត្រូវបានចាត់ទុកថាជាបន្ទះមានភាពប្រកបដោយនិរន្តរភាព ដោយសារតែការប្រើប្រាស់ថាមពលប្រកបដោយប្រសិទ្ធភាព អាចកែច្នៃឡើងវិញបាន និងការកាត់បន្ថយសំណល់ក្នុងការសាងសង់។ បន្ទះភាគច្រើនផលិតដោយប្រើវត្ថុធាតុដើមដែលកែច្នៃវិញហើយ និងជួយសម្រេចបាននូវវិញ្ញាបនបត្រសំណង់បៃតង (Green Building Certifications) ដូចជា LEED។