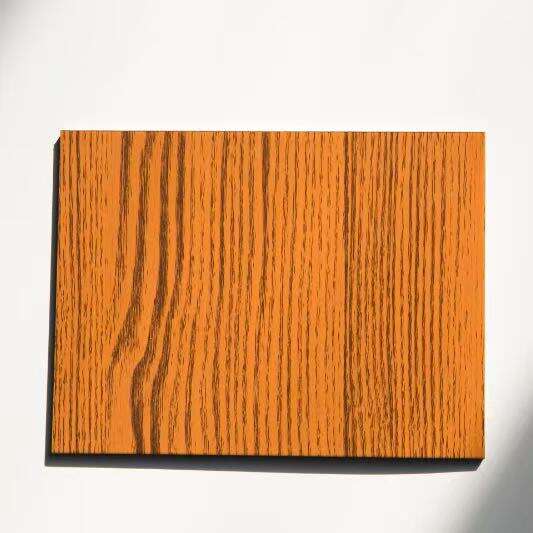

In today's construction landscape, aluminum composite panels have emerged as a frontrunner in eco-friendly building materials, offering a unique combination of durability, energy efficiency, and recyclability that makes them stand out in sustainable architecture. These innovative panels consist of two aluminum sheets bonded to a non-aluminum core, creating a material that delivers exceptional performance while minimizing environmental impact throughout its lifecycle. From production to installation and eventual recycling, aluminum composite panels demonstrate numerous ecological advantages that align with green building standards and sustainable development goals. Their growing popularity in modern construction reflects not just aesthetic appeal but also a conscientious approach to environmental responsibility in the building industry.

The exceptional strength-to-weight ratio of aluminum composite panels allows for significant reductions in material usage throughout building projects. Weighing substantially less than traditional cladding materials, these panels require less robust structural support systems, leading to decreased consumption of concrete, steel, and other framing materials. This lightweight characteristic also translates to lower transportation energy costs, as more panels can be shipped in a single load compared to heavier alternatives. The installation process benefits similarly, often requiring fewer personnel and less equipment to handle and position the panels, which further reduces the project's overall carbon footprint. During construction, the precision manufacturing of aluminum composite panels results in minimal jobsite waste, as panels arrive pre-finished and cut to specified dimensions when custom ordered.

Modern production of aluminum composite panels incorporates numerous energy-saving techniques that distinguish it from traditional building material manufacturing. The aluminum used in these panels typically contains a high percentage of recycled content, sometimes exceeding 90%, significantly reducing the energy-intensive process of refining virgin aluminum. Advanced coating technologies applied to aluminum composite panels require fewer application layers than conventional paint systems while delivering superior durability and color retention. The manufacturing process generates very little scrap material, and what little is produced gets recycled back into production streams. Energy-efficient curing ovens and powder coating systems have become standard in facilities producing high-quality aluminum composite panels, further reducing the environmental impact of production. These efficient processes contribute to the panels' impressive environmental product declarations and life cycle assessment ratings.

Aluminum composite panels contribute significantly to a building's energy efficiency through their exceptional thermal properties. The insulated core material in these panels creates an effective thermal break that reduces heat transfer through the building envelope. This thermal barrier performance helps maintain stable interior temperatures regardless of external weather conditions, leading to reduced demands on HVAC systems. Many aluminum composite panel systems now incorporate additional insulation layers that enhance their R-values beyond what traditional metal cladding can provide. The reflective properties of the aluminum surfaces help deflect solar radiation, particularly when light-colored finishes are specified, reducing cooling loads in warmer climates. These energy-saving characteristics make buildings clad with aluminum composite panels prime candidates for various green building certifications and energy efficiency incentives.

The precision engineering of aluminum composite panel systems creates exceptionally tight building envelopes that prevent uncontrolled air infiltration and exfiltration. This airtight construction minimizes energy losses associated with air leakage, which can account for significant portions of a building's heating and cooling demands. The non-porous nature of aluminum composite panels provides superior moisture resistance compared to many alternative cladding materials, preventing the insulation-degrading effects of water infiltration. Properly installed aluminum composite panel systems maintain their performance characteristics over decades without the deterioration often seen in other materials exposed to weather elements. The long-term consistency of their thermal performance ensures that energy savings continue throughout the building's lifespan, unlike some materials that degrade in efficiency over time.

Aluminum composite panels boast an impressive service life that frequently exceeds 30 years with proper maintenance, far outpacing many conventional cladding materials. The aluminum surfaces resist corrosion through natural oxide layer formation and advanced coating technologies that protect against environmental degradation. This durability translates to fewer material replacements over a building's lifespan, significantly reducing the cumulative environmental impact associated with recladding projects. The panels maintain their aesthetic appeal over time thanks to fade-resistant finishes that retain their color vibrancy for decades. Impact resistance is another notable feature of aluminum composite panels, as they withstand hail, minor collisions, and severe weather events better than many alternative materials, preventing premature replacement needs. The combination of these durability factors makes aluminum composite panels a sustainable choice that minimizes resource consumption over the long term.

When aluminum composite panels eventually reach the end of their service life, they offer superior recyclability compared to most cladding alternatives. The aluminum components can be infinitely recycled without loss of quality, requiring only 5% of the energy needed to produce primary aluminum. Specialized recycling facilities can separate the aluminum layers from the core material, allowing both components to enter appropriate recycling streams. The recycling rate for aluminum from construction applications continues to rise as collection infrastructure improves and awareness grows. Many manufacturers now operate take-back programs that ensure proper end-of-life processing of their aluminum composite panels. This closed-loop potential significantly reduces the panels' environmental footprint by keeping valuable materials out of landfills and reducing demand for virgin resources. The high scrap value of aluminum provides economic incentive for proper recycling, creating a sustainable cycle that benefits both the environment and the construction industry.

The installation advantages of aluminum composite panels contribute significantly to their environmental benefits. The lightweight nature of the panels allows for faster installation times compared to heavier cladding materials, reducing the duration of construction site operations and associated emissions. Many aluminum composite panel systems feature innovative attachment methods that minimize the need for intensive on-site modifications or specialized tools. The precision fabrication of these panels results in clean, efficient installations with minimal jobsite waste generation. Reduced installation times also translate to lower energy consumption at the construction site, as fewer equipment hours are required to complete the cladding process. The modular nature of aluminum composite panel systems enables easier future modifications or repairs, extending the building's usable life and preventing premature demolition.

The low-maintenance characteristics of aluminum composite panels represent another environmental advantage over competing cladding materials. Unlike some surfaces that require frequent repainting or refinishing, aluminum composite panels maintain their appearance with simple periodic cleaning using mild detergents and water. This eliminates the need for harsh chemical cleaners or energy-intensive maintenance procedures. The durable finishes resist staining, graffiti, and environmental pollutants, often allowing cleaning with just water pressure washing. The reduced maintenance frequency means fewer cleaning products entering wastewater systems and lower energy consumption associated with upkeep activities. Over decades of service, these minimized maintenance requirements accumulate significant environmental benefits compared to materials that demand more intensive care.

Aluminum composite panels can contribute valuable points toward various green building certification programs, including LEED, BREEAM, and Green Globes. Their recycled content helps projects earn materials and resources credits, while their energy-efficient properties support energy optimization goals. Many aluminum composite panel products carry environmental product declarations that provide the transparency required for modern sustainable construction documentation. The reduced jobsite waste associated with these panels aids in construction waste management credits. Some aluminum composite panel finishes even qualify for cool roof ratings in certain configurations, further enhancing their sustainability profile. Architects and builders increasingly specify aluminum composite panels specifically for their ability to help projects achieve higher levels of green building certification.

The reflective properties of aluminum composite panels play a significant role in mitigating urban heat island effects, particularly when light-colored finishes are selected. By reflecting rather than absorbing solar radiation, these panels help reduce localized temperature increases common in dense urban areas. Some specialized aluminum composite panel finishes are engineered to maximize solar reflectance while maintaining desired aesthetic qualities. This heat island mitigation effect contributes to lower ambient temperatures in urban environments, reducing cooling demands across entire neighborhoods rather than just individual buildings. The durability of the panels' reflective properties ensures these benefits persist throughout the product's lifespan, unlike some materials that lose reflectivity over time due to weathering or surface degradation.

The aluminum layers in these panels often contain 85-95% recycled content, while the percentage varies by manufacturer and specific product line.

Yes, their thermal break properties provide excellent insulation value that performs well in both cold and hot climate conditions.

Absolutely, the aluminum components are 100% recyclable and many manufacturers operate take-back programs to ensure proper recycling.